- HOME

- ABOUT US

- SERVICES

-

LICENCE & CERTIFICATION

- BIS (ISI MARK) FOR FOREIGN MANUFACTURERS

- DOMESTIC PRODUCT CERTIFICATION (ISI MARK)

- BIS SCHEME X CERTIFICATION

- BIS CERTIFICATE OF CONFORMITY (CoC)

- BIS HALLMARKING

- REACH CERTIFICATION (GLOBAL)

- LABORATORY RECOGNITION SCHEME (LRS)

- WORLD MANUFACTURER IDENTIFIER (WMI) CODE

- ECO MARK

- TAC APPROVAL FOR AUTOMOBILE

- PESO CERTIFICATION

- SASO CERTIFICATION

- CDSCO CERTIFICATION

-

REGISTRATION

- BIS (CRS) REGISTRATION FOR ELECTRONIC PRODUCT

- WPC-ETA APPROVAL

- BEE CERTIFICATION

- E-WASTE MANAGEMENT (EPR)

- EPR REGISTRATION FOR PLASTIC WASTE MANAGEMENT

- EPR REGISTRATION FOR BATTERY WASTE MANAGEMENT

- EPR REGISTRATION FOR USED OIL

- LEGAL METROLOGY (LMPC)

- TEC/MTCTE APPROVAL

- CE CERTIFICATION

- UL CERTIFICATION

- ROHS LICENCE

- DRONE REGISTRATION

- MOEF LICENCE

-

AUXILIARY

- STANDARDIZATION (SCIENTIFIC) DIVISION

- TRAINING SERVICES (NATIONAL & INTERNATIONAL)

- IMPORT/EXPORT LICENCE

- FSSAI CERTIFICATION

- MSME/SSI/NSIC REGISTRATION

- ISO REGISTRATION

- BRAND REPRESENTATION

- LABORATORY EQUIPMENT AND SETUP

- TRADEMARK REGISTRATION

- MAKE IN INDIA SUPPORT

- AG-MARK LICENCE

- THIRD PARTY INSPECTION AND MONITORING SERVICES

-

- PORTFOLIO

- UPDATES

- CONTACT

- LOGIN

EPR Registration for E-Waste Management

[ Table Of Content ]

- What is E-Waste?

- What is E Waste Management?

- EPR Registration for Manufacturers & Importer

- E-Waste Management Rule 2022

- Benefits of EPR Registration Certificate

- Product List for EPR Registration

- EPR Registration Process

- Documents Required for EPR Registration

- Timeline

- EPR Registration Fees

- Frequently Asked Questions (FAQ)

What is E-Waste?

E-waste is one of the world's fastest-growing trash streams. India currently produces nearly 50 million tonnes of it per year, and the number is going to rise as electronic products become more widely available. E-waste, or electronic garbage, refers to obsolete, unwanted, or defective electrical and electronic equipment. That includes everything from smartphones to refrigerators that have reached the end of their useful lives.

"Refuse what you do not need; Reduce what you do need;

Reuse what you consume;

Recycle what you cannot refuse, reduce, or reuse;

And compost the rest"

E-waste contains a laundry list of compounds that are hazardous to humans and the environment, including mercury, lead, beryllium, brominated flame retardants, and cadmium, to name a few. These chemicals get up in our land, water, and air when electronics are mismanaged during disposal. Because electronic devices contain the most lethal chemicals and metal, e-waste is far more toxic than much other municipal garbage. Long-term exposure to these chemicals harms the brain, kidney, bone systems, and the reproductive and endocrine systems.

What is E Waste Management and How to achieve it?

E Waste Management is the technique of collecting the e-waste, recycling, reuse, and disposal it in an environmental friendly manner to minimize its harmful impact on environment and human health. E-Waste management has become a major challenge as it directly affects human health and the environment, and this is happening due to the lack of awareness. The growing problem of E-waste calls for greater emphasis on recycling E-waste and better E-management.

Proper control over the material used in the manufacturing process is important to reduce waste generation (Freeman1989). The quantity of waste generated can be reduced by reducing the number of hazardous materials used in the process and the amount of excess raw materials in stock. This can be done in two ways, i.e., establishing material-purchase review and control procedures and inventory tracking system.

TODAY'S ELECTRONIC ------- GADGET

TOMMORROW'S ELECTRONIC -------- WASTE

EPR Registration for Manufacturers and Importers

The government passed the first law in 2011, based on Extended Producer Responsibility (EPR), which makes the manufacturer liable for managing the final stage of the life of its product in an eco-friendly way and ensures environmentally sound management. An Extended Producer's Responsibility (EPR) certificate or license is mandatory for every producer/importer producing electric or electrical equipment. It encourages manufacturers to produce environment-friendly products. EPR Authorization is issued by the Central Pollution Control Board (CPCB) under MoEFCC, Government of India.

As per the E-Waste (Management) Rules, 2016, all the manufacturers of Electrical and Electronics (EEE) products/equipments listed in schedule 1 are responsible for collecting, recycling and disposing the final stage of their EEE product from an authorized dismantler/recycler. As per the guidelines, manufacturers, and importers needs to tie-up with the authorized recycler to dispose of the E-Waste and submit all the plans related to the estimated dump quantity and method adopted for disposal in CPCB to get the EPR Certificate. In short, the product's manufacturer is responsible for the product's ultimate recycling, reuse, or disposal.

EPR - E-Waste (Management) Rules 2022

The Ministry of Environment, Forests, and Climate Change issued E-Waste (Management) Rules 2022 on November 2, 2022. This will go into effect on April 1, 2023.

As per this regulation, all manufacturers, producers, refurbishers, and recyclers shall have to register on the portal and collect e-waste generated during the manufacturing, refurbishing, or disposal of any electrical and electronic equipment and ensure its recycling or disposal. The Entities must register on the portal under the appropriate category, such as manufacturer, producer, refurbisher, or recycler. If an entity falls into more than one category, it must register under each category separately. It is illegal for any entity to conduct business without registration.

All entities shall have to file annual and quarterly returns in the prescribed form on the portal on or before the end of the month following the quarter or year to which the return relates.

These regulations shall apply to all manufacturers, producers, refurbishers, dismantlers, and recyclers engaged in the manufacture, sale, transfer, purchase, refurbishment, dismantling, recycling, and processing of e-waste or electrical and electronic equipment listed in Schedule I.

The Central Pollution Control Board may charge registration fees and annual maintenance fees on entities seeking registration under these rules based on the capacity of e-waste generated, recycled or handled by them, as determined by the Central Pollution Control Board with the approval of the Steering Committee.

The producer of electrical and electronic equipment listed in Schedule I must first register on the portal to obtain and implement extended producer responsibility targets as per Schedule III and IV.

Producers who have extended producer responsibility plans under the provisions of the erstwhile E-Waste (Management) Rules, 2016, shall migrate under these rules in accordance with the procedure established by the Central Pollution Control Board with the approval of the Steering Committee.

Benefits of EPR Registration Certificate

- EPR promotes the recycling and reuse of the e-waste (Electrical and electronics waste), hence reduces the cost of raw material for the producers/manufacturers.

- EPR ensures the management of e-waste in environmentally friendly manner, hence reduce the harmful impact of e-waste on environment.

- EPR Authorization from Central Pollution Control Board (CPCB) enhance the goodwill of the product and brand reputation in the market.

- EPR promotes sustainable development, hence lowers the waste generation and misuse of the natural resources.

Mandatory Products List for EPR Registration

The two major product categories that require EPR Authorization are as follows.

- Information Technology and Telecommunication equipment

- Consumer Electrical and Electronics

Following are the list of products that require mandatory EPR Authorization for uninterrupted manufacturing and selling in the Indian market.

| S.No. | Categories of electrical and electronic equipment | EEE Code | Average Life |

|---|---|---|---|

| 1 | Centralized data processing: Mainframe | ITEW1 | 10 |

| 2 | Centralized data processing: Minicomputers | ITEW1 | 5 |

| 3 | Personal Computing: Personal Computers (Central Processing Unit with input and output devices) | ITEW2 | 6 |

| 4 | Personal Computing: Laptop Computers(Central Processing Unit with input and output devices) | ITEW3 | 5 |

| 5 | Personal Computing: Notebook Computers | ITEW4 | 5 |

| 6 | Personal Computing: Notepad Computers | ITEW5 | 5 |

| 7 | Printers including cartridges | ITEW6 | 10 |

| 8 | Copying equipment | ITEW7 | 8 |

| 9 | Electrical and electronic typewriters | ITEW8 | 5 |

| 10 | User terminals and systems | ITEW9 | 6 |

| 11 | Facsimile | ITEW10 | 10 |

| 12 | Telex | ITEW11 | 5 |

| 13 | Telephones | ITEW12 | 9 |

| 14 | Pay telephones | ITEW13 | 9 |

| 15 | Cordless telephones | ITEW14 | 9 |

| 16 | Cellular telephones : Feature phones | ITEW15 | 7 |

| 17 | Cellular telephones : Smart phones | ITEW15 | 5 |

| 18 | Answering systems | ITEW16 | 5 |

| 19 | Television sets (including sets based on Liquid Crystal Display and Light Emitting Diode technology) | CEEW1 | 9 |

| 20 | Refrigerator | CEEW2 | 10 |

| 21 | Washing Machine | CEEW3 | 9 |

| 22 | Air-conditioners excluding centralized air conditioning plants | CEEW4 | 10 |

| 23 | Fluorescent and other Mercury containing lamps | CEEW5 | 2 |

| 24 | Products or equipment of Transmitting sound, images or other information by Telecommunications Bluetooth enabled devices | ITEW17 | 3 |

| 25 | Products or equipment of Transmitting sound, images or other information by Telecommunications Telecommunication Antenna | ITEW17 | 7 |

| 26 | Products or equipment of Transmitting sound, images or other information by Telecommunications Transmitters | ITEW17 | 5 |

| 27 | Products or equipment of Transmitting sound, images or other information by Telecommunications - Wi-Fi/wireless enabled Devices | ITEW17 | 3 |

| 28 | walkie talkie | ITEW17 | 5 |

| 29 | Products or equipment of Transmitting sound, images or other information by Telecommunications Radio/Satellite Telephone | ITEW17 | 7 |

| 30 | BTS (all components excluding structure of tower) | ITEW18 | 15 |

| 31 | Tablets, I-PAD | ITEW19 | 5 |

| 32 | Phablets | ITEW20 | 5 |

| 33 | Scanners | ITEW21 | 5 |

| 34 | Routers | ITEW22 | 10 |

| 35 | GPS | ITEW23 | 5 |

| 36 | UPS -upto 2 KVA | ITEW24 | 7 |

| 37 | UPS -greater than 2 KVA | ITEW24 | 10 |

| 38 | INVERTER -upto 2 KVA | ITEW25 | 7 |

| 39 | INVERTER -greater than 2 KVA | ITEW25 | 10 |

| 40 | Modems | ITEW26 | 5 |

| 41 | ELECTRONIC DATA STORAGE DEVICES FOR FLASH DRIVE (SMALL DEVICES) | ITEW27 | 5 |

| 42 | ELECTRONIC DATA STORAGE DEVICES FOR LARGE DRIVE LIKE SERVER | ITEW27 | 10 |

| 43 | Screen, Electronic Photo frames, Electronic Display Panel, Monitors | CEEW6 | 7 |

| 44 | Radio sets | CEEW7 | 8 |

| 45 | Set top Boxes | CEEW8 | 8 |

| 46 | Video Cameras | CEEW9 | 10 |

| 47 | Video Recorders | CEEW10 | 5 |

| 48 | Hi-Fi Recorders | CEEW11 | 5 |

| 49 | Audio Amplifiers | CEEW12 | 10 |

| 50 | Other products or equipment for the purpose of recording or reproducing sound or images including signals and other technologies for the distribution of sound and image by telecommunications - CCTV Camera with DVR & NVR | CEEW13 | 7 |

| 51 | Other products or equipment for the purpose of recording or reproducing sound or images including signals and other technologies for the distribution of sound and image by telecommunications Projector | CEEW13 | 7 |

| 52 | Other products or equipment for the purpose of recording or reproducing sound or images including signals and other technologies for the distribution of sound and image by telecommunications - Digital sound and video recorder and player | CEEW13 | 7 |

| 53 | Other products or equipment for the purpose of recording or reproducing sound or images including signals and other technologies for the distribution of sound and image by telecommunications - Others products or equipment for the purpose of recording or reproducing sound or images including signals and other technologies for the distribution of sound and image by telecommunications | CEEW13 | 7 |

| 54 | HDCOM USED FOR VIDEO CONFERENCING | CEEW13 | 10 |

| 55 | Solar panels/cells, solar Photovoltaic panels/cells/modules. | CEEW14 | 15 |

| 56 | Luminaires for fluorescent lamps with the exception of luminaires in households | CEEW15 | 2 |

| 57 | High intensity discharge lamps, including pressure sodium lamps and metal halide lamps | CEEW16 | 2 |

| 58 | Low pressure sodium lamps | CEEW17 | 2 |

| 59 | Other lighting or equipment for the purpose of spreading or controlling light excluding filament bulbs -LED BULBS/TUBES/CONSUMER LUMINARIES & CONSUMER LED DRIVES | CEEW18 | 4 |

| 60 | Other lighting or equipment for the purpose of spreading or controlling light excluding filament bulbs -PROFESSIONALS LUMINARIES & DRIVES | CEEW18 | 8 |

| 61 | Digital camera | CEEW19 | 5 |

| 62 | Large cooling appliances | LSEEW1 | 10 |

| 63 | Freezers | LSEEW2 | 10 |

| 64 | Other large appliances used for refrigeration, conservation and storage of food | LSEEW3 | 10 |

| 65 | Clothes dryers | LSEEW4 | 10 |

| 66 | Dish Washing Machines | LSEEW5 | 10 |

| 67 | Electric cookers | LSEEW6 | 7 |

| 68 | Electric stoves | LSEEW7 | 7 |

| 69 | Electric hot plates | LSEEW8 | 5 |

| 70 | Microwaves, Microwave Oven | LSEEW9 | 10 |

| 71 | Other large appliances used for cooking and other processing of food | LSEEW10 | 10 |

| 72 | Electric heating appliances | LSEEW11 | 10 |

| 73 | Electric radiators | LSEEW12 | 7 |

| 74 | Other large appliances for heating rooms, beds, seating furniture | LSEEW13 | 7 |

| 75 | Electric fans | LSEEW14 | 10 |

| 76 | Other fanning, exhaust ventilation and conditioning equipment | LSEEW15 | 10 |

| 77 | Vacuum cleaners | LSEEW16 | 10 |

| 78 | Carpet sweepers | LSEEW17 | 10 |

| 79 | Other appliances for cleaning | LSEEW18 | 10 |

| 80 | Appliances used for sewing, knitting, weaving and other processing for textiles | LSEEW19 | 7 |

| 81 | Iron and other appliances for ironing, mangling and other care of clothing - Dry iron | LSEEW20 | 15 |

| 82 | Iron and other appliances for ironing, mangling and other care of clothing - Steam Iron/Garment Steamer | LSEEW20 | 10 |

| 83 | Grinders, coffee machines and equipment for opening or sealing containers or packages | LSEEW21 | 10 |

| 84 | Smoke detector | LSEEW22 | 10 |

| 85 | Heating Regulators | LSEEW23 | 5 |

| 86 | Thermostats | LSEEW24 | 5 |

| 87 | Automatic dispensers for hot drinks | LSEEW25 | 7 |

| 88 | Automatic dispensers for hot or cold bottles or cans | LSEEW26 | 7 |

| 89 | Automatic dispensers for solid products | LSEEW27 | 10 |

| 90 | Automatic dispensers for money | LSEEW28 | 10 |

| 91 | All appliances which deliver automatically all kinds of products | LSEEW29 | 10 |

| 92 | Indoor air purifier | LSEEW30 | 10 |

| 93 | Hair dryer | LSEEW31 | 5 |

| 94 | Electric shaver | LSEEW32 | 5 |

| 101 | Tools for riveting, nailing or screwing or removing rivets, nails, screws or similar uses | EETW5 | 10 |

| 102 | Tools for welding, soldering, or similar use | EETW6 | 10 |

| 103 | Equipment for spraying, spreading, dispersing or other treatment of liquid or gaseous substance by other means | EETW7 | 10 |

| 104 | Tools for mowing or other gardening activities | EETW8 | 10 |

| 105 | Electrical trains or car racing sets | TLSEW1 | 2 |

| 106 | Hand-held video games consoles | TLSEW2 | 2 |

| 107 | Video games | TLSEW3 | 2 |

| 108 | Computers for biking, diving, running, rowing, etc. | TLSEW4 | 5 |

| 109 | Sports equipment with electric or electronic components | TLSEW5 | 5 |

| 110 | Coin slot machines | TLSEW6 | 8 |

| 111 | Radiotherapy equipment and accessories | MDW1 | 20 |

| 112 | Cardiology equipment and accessories | MDW2 | 10 |

| 113 | Dialysis equipment and accessories | MDW3 | 10 |

| 114 | Pulmonary ventilators and accessories - Diagnostic Cardiology | MDW4 | 7 |

| 115 | Pulmonary ventilators and accessories - Anaesthesia & Respiratory | MDW4 | 10 |

| 116 | Nuclear Medicine Equipment and accessories | MDW5 | 20 |

| 117 | Laboratory equipment for in vitro diagnosis and accessories | MDW6 | 15 |

| 118 | Analysers and accessories | MDW7 | 10 |

| 119 | Magnetic Resonance Imaging (MRI), Positron Emission Tomography (PET) Scanner, Computed Tomography Scanner, & Ultrasound Equipment along with accessories - MRI | MDW8 | 15 |

| 120 | Magnetic Resonance Imaging (MRI), Positron Emission Tomography (PET) Scanner, Computed Tomography Scanner, & Ultrasound Equipment along with accessories - PET CT/PET | MDW8 | 20 |

| 121 | Magnetic Resonance Imaging (MRI), Positron Emission Tomography (PET) Scanner, Computed Tomography Scanner, & Ultrasound Equipment along with accessories - SPECT CT/ SPECT | MDW8 | 20 |

| 122 | Magnetic Resonance Imaging (MRI), Positron Emission Tomography (PET) Scanner, Computed Tomography Scanner, & Ultrasound Equipment along with accessories - CT | MDW8 | 15 |

| 123 | Magnetic Resonance Imaging (MRI), Positron Emission Tomography (PET) Scanner, Computed Tomography Scanner, & Ultrasound Equipment along with accessories US | MDW8 | 10 |

| 124 | Magnetic Resonance Imaging (MRI), Positron Emission Tomography (PET) Scanner, Computed Tomography Scanner, & Ultrasound Equipment along with accessories - Computed Tomography | MDW8 | 20 |

| 125 | Magnetic Resonance Imaging (MRI), Positron Emission Tomography (PET) Scanner, Computed Tomography Scanner, & Ultrasound Equipment along with accessories - Ultrasound Diagnostic Imaging | MDW8 | 10 |

| 126 | Fertilization tests equipment and accessories | MDW9 | 10 |

| 127 | Other electric appliances/equipment/kits used for preventing, screening, detecting, monitoring, evaluating, reviewing, examining, investigating, probing, treating illness sickness, disease, disorder, affliction, infection, injury, trauma, abuse or disability including the Mobiles, Tablets or any other device with the features having the potential of sex selection and their accessories- Maternal & Infant care products | MDW10 | 7 |

| 128 | Other electric appliances/equipment/kits used for preventing, screening, detecting, monitoring, evaluating, reviewing, examining, investigating, probing, treating illness sickness, disease, disorder, affliction, infection, injury, trauma, abuse or disability including the Mobiles, Tablets or any other device with the features having the potential of sex selection and their accessories- C-Arm | MDW10 | 12 |

| 129 | Other electric appliances/equipment/kits used for preventing, screening, detecting, monitoring, evaluating, reviewing, examining, investigating, probing, treating illness sickness, disease, disorder, affliction, infection, injury, trauma, abuse or disability including the Mobiles, Tablets or any other device with the features having the potential of sex selection and their accessories - Monitoring Solution products/High end | MDW10 | 15 |

| 130 | Other electric appliances/equipment/kits used for preventing, screening, detecting, monitoring, evaluating, reviewing, examining, investigating, probing, treating illness sickness, disease, disorder, affliction, infection, injury, trauma, abuse or disability including the Mobiles, Tablets or any other device with the features having the potential of sex selection and their accessories - X-ray and fluoroscopy | MDW10 | 12 |

| 131 | Other electric appliances/equipment/kits used for preventing, screening, detecting, monitoring, evaluating, reviewing, examining, investigating, probing, treating illness sickness, disease, disorder, affliction, infection, injury, trauma, abuse or disability including the Mobiles, Tablets or any other device with the features having the potential of sex selection and their accessories - Mammography devices | MDW10 | 12 |

| 132 | Other electric appliances/equipment/kits used for preventing, screening, detecting, monitoring, evaluating, reviewing, examining, investigating, probing, treating illness sickness, disease, disorder, affliction, infection, injury, trauma, abuse or disability including the Mobiles, Tablets or any other device with the features having the potential of sex selection and their accessories - Other electric appliances/equipment/kits used for preventing, screening, detecting, monitoring, evaluating, reviewing, examining, investigating, probing, treating illness sickness, disease, disorder, affliction, infection, injury, trauma, abuse or disability including the Mobiles, Tablets or any other device with the features having the potential of sex selection and their accessories | MDW10 | 7 |

| 133 | Gas analyser | LIW1 | 8 |

| 134 | Equipment having electrical and electronic components | LIW2 | 8 |

Latest Government Notification

IMPORTANT NOTIFICATION FOR PRODUCERS OF E-WASTE : E-WASTE MANAGEMENT RULES 2022How to Apply for EPR Authorization?

The process of EPR Authorization or EPR Registration involves the following steps mentioned below:

- Documentation: Applicant needs to prepare all required document with EPR Plan for EPR authorization before submission of the application.

- Filling Application in prescribed format: Applicant needs to fill detailed information in prescribed application form with EPR plan.

- Offline submission of application: Applicant need to submit offline application with detailed information of producer and EPR plan to concerned department.

- Scrutiny of application: CPCB official will scrutinize the application and EPR plan is evaluated by CPCB for approval. If the documents presented are incomplete then CPCB official may respond with checklist within 25 days for clarification purpose.

- Grant of EPR approval: Chairman of CPCB shall approve the EPR plan as scrutinized by concerned officials. After approval of EPR plan, the divisional head issues the EPR authorization.

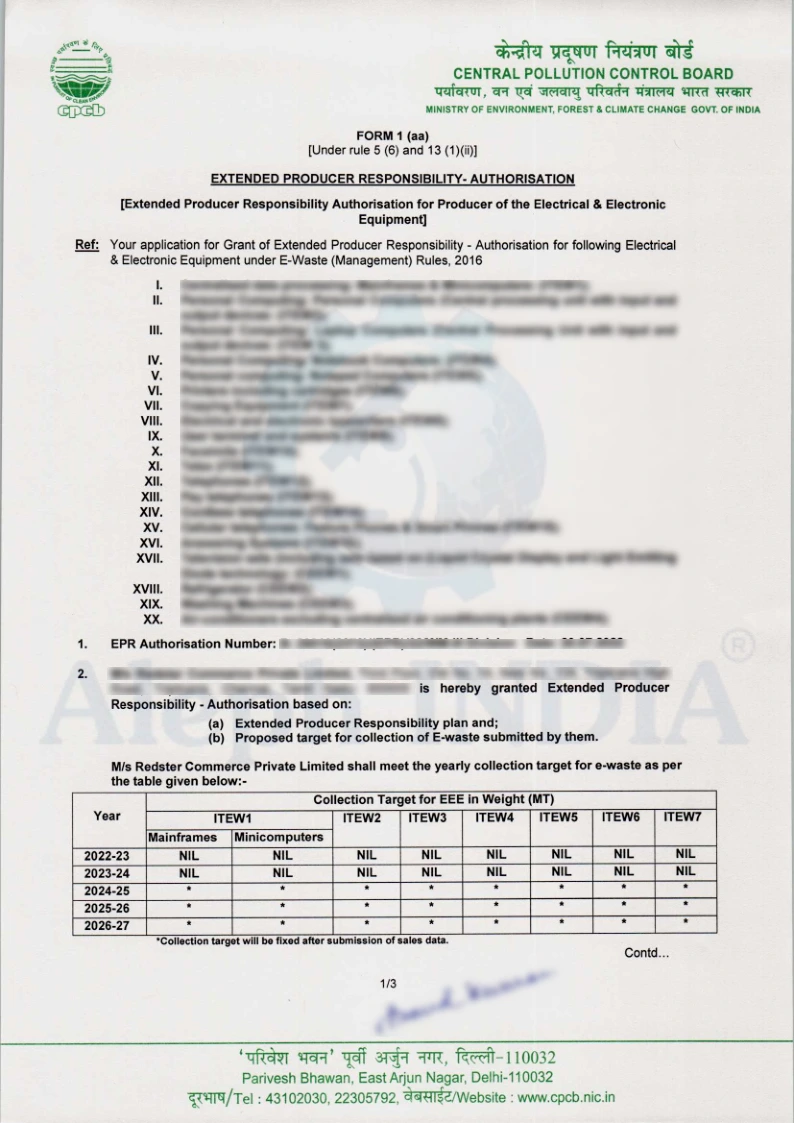

Sample of a Grant Certificate for EPR

Documents Required for EPR Registration

The following documents are required to be submitted along with Form-1:

- Address proof documents of the Manufacturer/Importer.

- GST Certificate with address of Manufacturing Unit.

- Copy of documents/certificate of Company Registrar or Directorate of Company, or Import Export code letter.

- Copies of agreement document with dealers, collection centers, dismantlers, recyclers, treatment, storage and disposal facilities (TSDFs) etc.

- Self-declaration for compliance of RoHS in prescribed format.

- The technical documents (supplier declaration- description of product, document for materials, parts, and/or sub-assemblies and analytical test result)

- Copy of the permissions/licenses from the relevant ministry/department for marketing various products or for doing the business as given below:

- TIN details

- PAN details

- Incorporation certificate

- Copy IEC in case of importers

- Copy of authorization issued by the SPCBs/PCCs

- Documents related to EPR plan.

- Details of proposed awareness programmes and allied initiatives.

- Estimated budget earmarked for Extended Producer Responsibility (EPR)

TIMELINE

CPCB shall provide EPR authorization within 120 days of receiving a complete application, as per E-Waste regulations. In case of incomplete application, the CPCB may verify the application and respond with a check list within 25 days.

Note: Agreement will be signed for 1 year, and the Certificate granted will be valid for 5 years.

EPR Registration Fees

Know the complete details about the EPR Registration Fees by contacting our EPR Registration expert team. Get the best quotation, fill out the above form.

How can Aleph INDIA help in obtaining the EPR Registration Certificate?

Aleph INDIA has a team of experts that can help you to obtain your EPR Authorization/EPR Certificate. We are the leading EPR Registration consultant in Delhi helping our clients to get EPR Registration in any part of India.

Our EPR consultant team helps the EPR Authorization applicants during every steps of the registration process, from documents preparation to grant of license. We directly coordinate with the CPCB officials for proper documentation and information flow during the whole certification process with proper follow-ups. For more information, connect with our experts team.

frequently asked questions (FAQ)

E-waste refers to electronic products nearing the end of their "useful life", for example, computers, televisions, VCRs, stereos, copiers, and fax machines. Many of these products can be reused, refurbished, or recycled.

Reduce, reuse, and recycle. Reduce your generation of e-waste through smart procurement and good maintenance. Reuse still functioning electronic equipment by donating or selling it to someone. Recycle those components that cannot be repaired. Most electronic devices contain a variety of materials, including metals that can be recycled.

Extended Producer Responsibility (EPR) is a policy approach in which a producer's physical and /or financial responsibility for a product extended to the post-consumer stage of a product's life cycle. It is important because it motivates the producers to manufacture environmentally friendly products and reduce pollution.

Yes, EPR is mandatory for some products in India. For more details, you can contact us.

The present policy ensures that every electrical and electronic equipment producer and their spare parts do not contain pollutants such as lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls, and polybrominated diphenyl ethers beyond a maximum concentration value. Every producer shall provide detailed information on the constituents of the equipment and their components or consumables or parts or spares, along with a declaration of conformance to the RoHS (Restriction of Hazardous Substances) provisions in the product user documentation.

EPR policies helped a lot in increasing the recycling activities and shown a positive effect on decreasing pollution. It has started showing positive effects throughout the country.

If you want EPR License urgently, gets in touch with our EPR Experts now.

Repair - Replace your throwaway habits with repairing ones and the safest way to go about them. Reuse - If your items are old but in good condition, you can turn them into money or donate them to someone who needs that product. Recycle - Plenty of non - profit organizations, local communities, and official organizations offer services to help you recycle old electronics.

As per CPCB (Central Pollution Control Board) guidelines, producers, importers, brand owners and manufacturers all can obtain EPR certificate for e-waste management through registration on EPR portal.

Advantages of Reporting Waste Generation through EPR Registration with CPCB, SPCB, and Pollution Control Committees:

- Promotes effective waste management practices

- Contributes to a cleaner and healthier environment

- Helps prevent water, air, and soil pollution

- Reduces the risk of soil erosion

- Fosters entrepreneurship and green innovation

- Ensures access to cost-effective recycled resources

BIS REGISTRATION FOR ELECTRONIC & IT PRODUCT

In the era of globalization, world trade is growing rapidly and henceforth, Manufacturing and Import/Export businesses are also growing drastically...View More

BIS CERTIFICATE FOR FOREIGN MANUFACTURER

The Economy of India-the fastest developing economy on the globe with the capabilities that help it matches up with the biggest international...View More

PRODUCT CERTIFICATION SCHEME (ISI MARK) FOR DOMESTIC MANUFACTURERS

Anything a person buys from food to cars, clothes to electronics, branded to unnamed products there is always a question that wanders in one’s...View More

WIRELESS PLANNING AND COORDINATION (WPC)

WPC: Wireless means communication done from one point to another point without the wires and cables. Electromagnetic waves carry the ...View More

BUREAU OF ENERGY EFFICIENCY (BEE) CERTIFICATE

BEE CERTIFICATE: Energy is the future, and its conservation is the way of the bright future. Everyone claims the environment is important...View More

E-WASTE MANAGEMENT

E-waste is one of the world's fastest-growing trash streams. We currently manufacture almost 50 million tones of it each year...View More

Request a call back.

Would you like to speak to one of our Senior Technical advisers over the phone? Just submit your details and we’ll be in touch shortly. You can also email us if you would prefer.

BIS REGISTRATION FOR ELECTRONIC & IT PRODUCT

In the era of globalization, world trade is growing rapidly and henceforth, Manufacturing and Import/Export businesses are also growing drastically...View More

BIS CERTIFICATE FOR FOREIGN MANUFACTURER

The Economy of India-the fastest developing economy on the globe with the capabilities that help it matches up with the biggest international...View More

PRODUCT CERTIFICATION SCHEME (ISI MARK) FOR DOMESTIC MANUFACTURERS

Anything a person buys from food to cars, clothes to electronics, branded to unnamed products there is always a question that wanders in one’s...View More

WIRELESS PLANNING AND COORDINATION (WPC)

WPC: Wireless means communication done from one point to another point without the wires and cables. Electromagnetic waves carry the ...View More

BUREAU OF ENERGY EFFICIENCY (BEE) CERTIFICATE

BEE CERTIFICATE: Energy is the future, and its conservation is the way of the bright future. Everyone claims the environment is important...View More

E-WASTE MANAGEMENT

E-waste is one of the world's fastest-growing trash streams. We currently manufacture almost 50 million tones of it each year...View More

View All Services

Request a call back.

Would you like to speak to one of our Senior Technical advisers over the phone? Just submit your details and we’ll be in touch shortly. You can also email us if you would prefer.