BIS Certification For Cold Formed Welded Carbon Steel Square and Rectangular Hollow Sections IS 18573:2024

Bureau of Indian Standards (BIS) has recently introduced a new standard IS 18573:2024, which is specifically designed for mechanical, general engineering and decorative purposes. It is a mandatory requirement for manufacturers to obtain BIS certification for cold formed welded carbon steel square and rectangular hollow sections under IS 18573:2024. This certification is important for mechanical, general engineering and decorative purposes, ensuring that products meet rigorous quality and safety requirements.

IS 18573:2024

IS 18573:2024, established by the Bureau of Indian Standards (BIS), comprehensively outlines the requirements for cold-formed square and rectangular welded hollow sections. This standard covers specifications related to materials, mechanical properties, dimensions, tolerances and surface protection. This ensures that manufacturers follow stringent quality measures to maintain product integrity and performance. This standard serves as a comprehensive guideline, detailing requirements for materials, mechanical properties, dimensions, tolerances, and surface protection for square and rectangular hollow sections. It classifies the sections into types or grades such as YSt 160, YSt 210, YSt 240, YSt 310, and YSt 355, offering flexibility to suit different engineering requirements.

Key highlights

| Product Name | Cold Formed Welded Carbon Steel Square and Rectangular Hollow Sections for Mechanical, General Engineering and Decorative Purposes |

| Applicable Indian Standard | IS 18573:2024 |

| Applicable Certification Scheme | Product Certification Scheme (ISI Mark Scheme) Scheme 1 - Schedule 2 |

| Compliance Requirement | Mandatory |

| QCO Link | - |

| Scope as per Standard |

|

Tests

The following are the major tests for Cold Formed Welded Carbon Steel Square and Rectangular Hollow Sections for Mechanical, General Engineering and Decorative Purposes.

- Ladle /Product Analysis

- Straightness

- Basics of calculation

- Length

- Dimensions & tolerances, Manufacturing

- Squareness of side

- External corner radius

- Straightness & twist

- Tensile Testing

- Surface Protection

BIS Certificate for Cold Formed Welded Carbon Steel Square and Rectangular Hollow Section 18573:2024 from BIS

BIS certification serves as an important framework established by the Government of India to ensure that only high-quality, reliable products are available in the market. BIS Certificate covers a wide range of industries and products, setting stringent standards and guidelines for compliance. BIS Certificate for Cold Formed Welded Carbon Steel Square and Rectangular Hollow Sections symbolizes an important framework established by the Government of India to ensure the quality, safety and reliability of the products available in the market. Manufacturers seeking BIS certification can connect with a BIS consultant like Aleph India, which is the leading cold formed welded carbon steel square and rectangular hollow section BIS consultant in India. Aleph India is committed to assist manufacturers in securing BIS license for their products while ensuring adherence to the required quality standards with unwavering excellence.

NOTE:

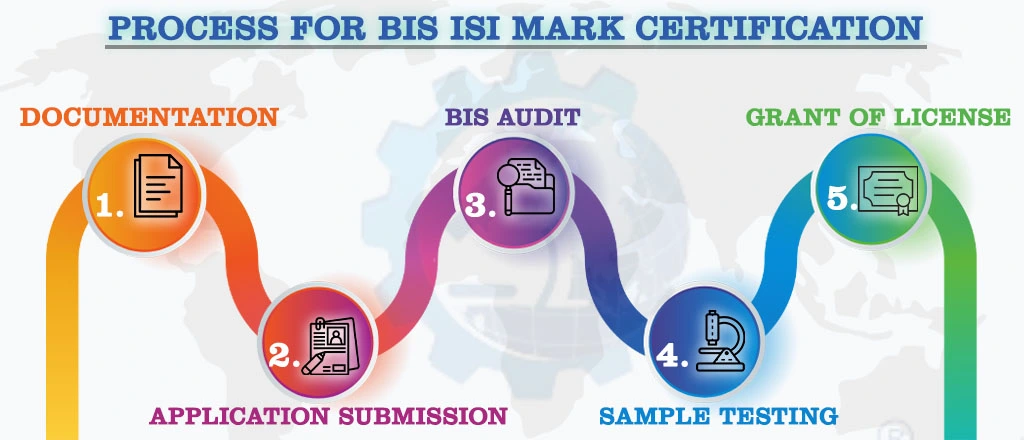

For Detailed Information about the Procedure for BIS ISI Certification, Visit :

Timeline for BIS Certification Cold Formed Welded Carbon Steel Square and Rectangular Hollow Sections

The approximate timeline to obtain BIS Certification for Cold Formed Welded Carbon Steel Square and Rectangular Hollow Sections to use ISI mark as Per IS 18573:2024 is given below:

- For Indian Manufacturers (Standard Timeframe – 30 days)

- For Foreign Manufacturers (Standard Timeframe – 180 days)

Conclusion:

The launch of IS 18573:2024 by the Bureau of Indian Standards (BIS) marks a significant advancement in the regulation of cold-formed welded carbon steel square and rectangular hollow sections. This standard mandates stringent quality and safety requirements for manufacturers, covering essential specifications such as materials, mechanical properties, dimensions, tolerances and surface protection. By achieving BIS certification, manufacturers demonstrate their commitment to manufacturing reliable and high quality products for mechanical, general engineering and decorative applications.

International Audits & Participation

Testimonials

BIS REGISTRATION FOR ELECTRONIC & IT PRODUCT

In the era of globalization, world trade is growing rapidly and henceforth, Manufacturing and Import/Export businesses are also growing drastically...View More

BIS CERTIFICATE FOR FOREIGN MANUFACTURER

The Economy of India-the fastest developing economy on the globe with the capabilities that help it matches up with the biggest international...View More

PRODUCT CERTIFICATION SCHEME (ISI MARK) FOR DOMESTIC MANUFACTURERS

Anything a person buys from food to cars, clothes to electronics, branded to unnamed products there is always a question that wanders in one’s...View More

WIRELESS PLANNING AND COORDINATION (WPC)

WPC: Wireless means communication done from one point to another point without the wires and cables. Electromagnetic waves carry the ...View More

BUREAU OF ENERGY EFFICIENCY (BEE) CERTIFICATE

BEE CERTIFICATE: Energy is the future, and its conservation is the way of the bright future. Everyone claims the environment is important...View More

E-WASTE MANAGEMENT

E-waste is one of the world's fastest-growing trash streams. We currently manufacture almost 50 million tones of it each year...View More

View All Services

Request a call back.

Would you like to speak to one of our Senior Technical advisers over the phone? Just submit your details and we’ll be in touch shortly. You can also email us if you would prefer.