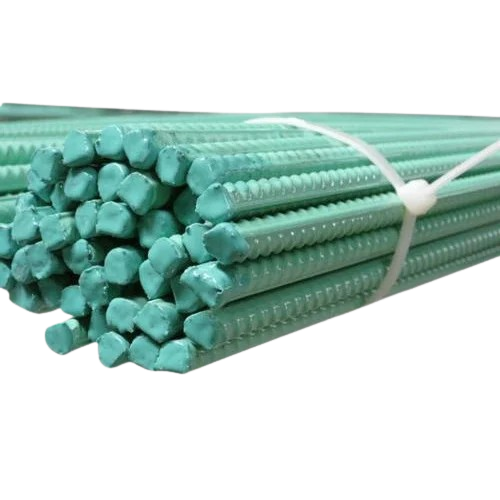

Fusion bonded epoxy coated reinforcing bars IS 13620:1993

Fusion bonded epoxy coated reinforcing bars (FBE rebars) are used to enhance the durability and longevity of concrete structures by providing superior corrosion resistance. These rebars are coated with a layer of epoxy resin, which is applied through a fusion bonding process, creating a strong, protective barrier against moisture, chemicals, and other corrosive elements. This coating prevents rust and deterioration of the steel reinforcement, thereby maintaining the structural integrity of the concrete over time. FBE rebars are particularly valuable in harsh environments such as coastal areas, industrial settings, and regions with high humidity or exposure to de-icing salts, ensuring the resilience and safety of bridges, highways, buildings, and other critical infrastructure projects.

Importance of BIS Certification

BIS certification is necessary for fusion bonded epoxy coated reinforcing bars to ensure they meet the stringent quality and safety standards established by the Bureau of Indian Standards. This certification guarantees that the rebars possess the required properties for effective corrosion resistance, durability, and structural integrity essential for their use in concrete reinforcement. By adhering to BIS standards, manufacturers can ensure that the epoxy coating is applied correctly and consistently, providing reliable protection against moisture and chemical exposure

Compliance with BIS certification fosters consumer confidence, ensures regulatory alignment, and supports the construction of high-quality, resilient infrastructure projects, thereby enhancing the safety and longevity of buildings, bridges, and other critical structures.

Indian Standard IS 13620:1993

As per the latest Quality Control Order (QCO) issued by the Ministry of Steel, Government of India, on 5th February 2024, fusion bonded epoxy coated reinforcing bars must adhere to the Indian Standard IS 13620:1993. This standard ensures that these reinforcing bars meet essential quality and safety criteria, including the proper application of the epoxy coating, which provides critical corrosion resistance and durability. Compliance with IS 13620:1993 guarantees that the bars are manufactured to precise specifications, ensuring their reliability and performance in reinforcing concrete structures. Adherence to this standard is crucial for manufacturers to align with regulatory guidelines, maintain product consistency, and foster consumer trust in the quality and safety of construction materials.

Key highlights

| Product Name | Fusion bonded epoxy coated reinforcing bars |

| Applicable Indian Standard | IS 13620:1993 |

| Applicable Certification Scheme | Product Certification Scheme (ISI Mark Scheme) Scheme 1 - Schedule 2 |

| Compliance Requirement | Mandatory |

| QCO Link | Fusion bonded epoxy coated reinforcing bars IS 13620:1993 |

| Scope as per Standard | This standard covers deformed steel reinforcing bars with protective epoxy coating applied by electrostatic spray method. |

Tests

The following are the major tests for Fusion Bonded Epoxy Coated Reinforcing Bars.

- Coating thickness

- Continuity of of coating

- Adhesion of coating

NOTE:

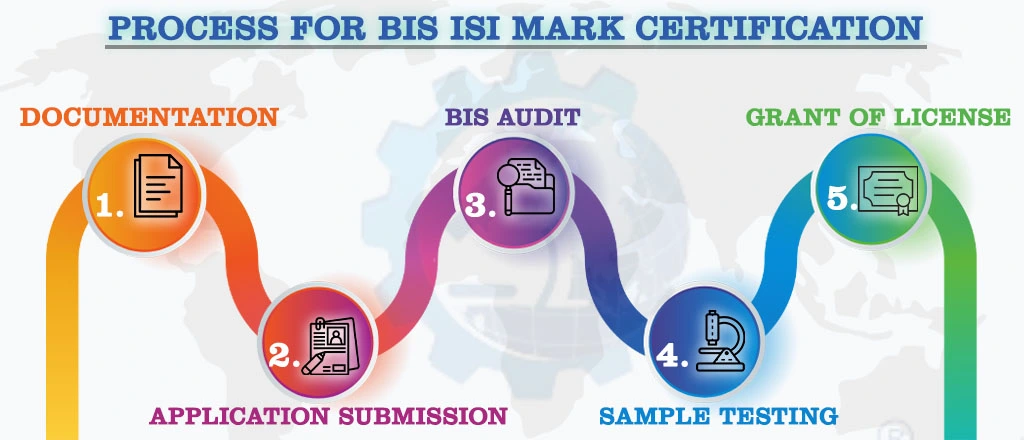

For Detailed Information about the Procedure for BIS ISI Certification, Visit :

Timeline for BIS Certification

The approximate timeline to obtain BIS certification for Fusion bonded epoxy coated reinforcing bars to use the ISI mark as per IS 13620:1993 is as follows:

- For Indian Manufacturers (Standard Timeframe – 30 days)

- For Foreign Manufacturers (Standard Timeframe – 180 days)

Conclusion:

Fusion bonded epoxy coated reinforcing bars (FBE rebars) are critical in enhancing the durability and longevity of concrete structures by providing superior corrosion resistance. The importance of BIS certification for these rebars cannot be overstated, as it ensures that the products meet stringent quality and safety standards essential for maintaining structural integrity in harsh environments. Adherence to Indian Standard IS 13620:1993, ensures that the epoxy coating is applied correctly, offering reliable protection against moisture and chemical exposure. Compliance with these standards fosters consumer confidence, supports regulatory alignment, and promotes the construction of high-quality, resilient infrastructure projects, thereby enhancing the safety and longevity of buildings, bridges, and other critical structures.

For more updates and detailed procedures, stay connected with Aleph INDIA and ensure your products are always compliant and top-quality.

International Audits & Participation

Testimonials

BIS REGISTRATION FOR ELECTRONIC & IT PRODUCT

In the era of globalization, world trade is growing rapidly and henceforth, Manufacturing and Import/Export businesses are also growing drastically...View More

BIS CERTIFICATE FOR FOREIGN MANUFACTURER

The Economy of India-the fastest developing economy on the globe with the capabilities that help it matches up with the biggest international...View More

PRODUCT CERTIFICATION SCHEME (ISI MARK) FOR DOMESTIC MANUFACTURERS

Anything a person buys from food to cars, clothes to electronics, branded to unnamed products there is always a question that wanders in one’s...View More

WIRELESS PLANNING AND COORDINATION (WPC)

WPC: Wireless means communication done from one point to another point without the wires and cables. Electromagnetic waves carry the ...View More

BUREAU OF ENERGY EFFICIENCY (BEE) CERTIFICATE

BEE CERTIFICATE: Energy is the future, and its conservation is the way of the bright future. Everyone claims the environment is important...View More

E-WASTE MANAGEMENT

E-waste is one of the world's fastest-growing trash streams. We currently manufacture almost 50 million tones of it each year...View More

View All Services

Request a call back.

Would you like to speak to one of our Senior Technical advisers over the phone? Just submit your details and we’ll be in touch shortly. You can also email us if you would prefer.