BIS CERTIFICATION FOR HOT ROLLED MILD STEEL SHEET & STRIP

IS 2385:1977

In this competitive scenario, it isn't easy to survive in the market without a standard quality and certified product. BIS license may also be required to sell products in the Indian market.

To get BIS certification and produce a standard quality product, the manufacturer must ensure that their product must follow the specified Indian standard.

Let's take a closer look at IS 2385:1977 for hot rolled mild steel sheets and strip in coil form for cold reduced tinplate and cold reduced blackplate.

This standard specifies the requirements for hot rolled mild steel sheets and strips in coil form for cold reduced tinplate and cold reduced blackplate production.

Material conforming to this standard must be supplied in coil form, typically in a thickness range of 1.8 mm or thicker, and in widths of 600 mm or greater. Because of the variety of finishes and other characteristics required in the final cold reduced product, the surface is extremely important.

When the end product requires special characteristics, the manufacturer and reroller must agree on the specification of the hot-rolled sheet/strip at the time of ordering. Slit widths of less than 600 mm from wide coils may be considered sheet/strip coils for rerolling. The general requirements for the supply of hot rolled mild steel sheet and strip for the production of cold reduced tinplate and blackplate shall be as specified.

The steel shall be produced using an open hearth, an electric furnace, a duplex furnace, a basic oxygen furnace, or a combination of these processes. The chemical composition of the material must meet standard specifications. The sheet and strip must be relatively free of laminations, seams, cracks, rolled-in oxides, inclusions, and other harmful defects that may affect the material during subsequent processing. Sheets and strips must be supplied hot rolled or hot rolled, pickled, and oiled.

Packing and Marking:

Sheets and strips must be tightly coiled, with one edge above the other. The amount of material protruding from the edges shall not exceed 5% of the width of the sheet strip. A maximum projection of 40 mm is permitted for sheets and strips with widths greater than 800 mm. Edge projection is not permitted on both sides of the coils.

Coils must be rigidly packed with high tensile steel strappings that are tied around the circumference and crosswise of each coil.

Each coil of sheet or strip must be legibly marked with the following information:

- Manufacturer’s name or trade mark

- Coil number

- Coil mass

- Product Dimensions

- Order number

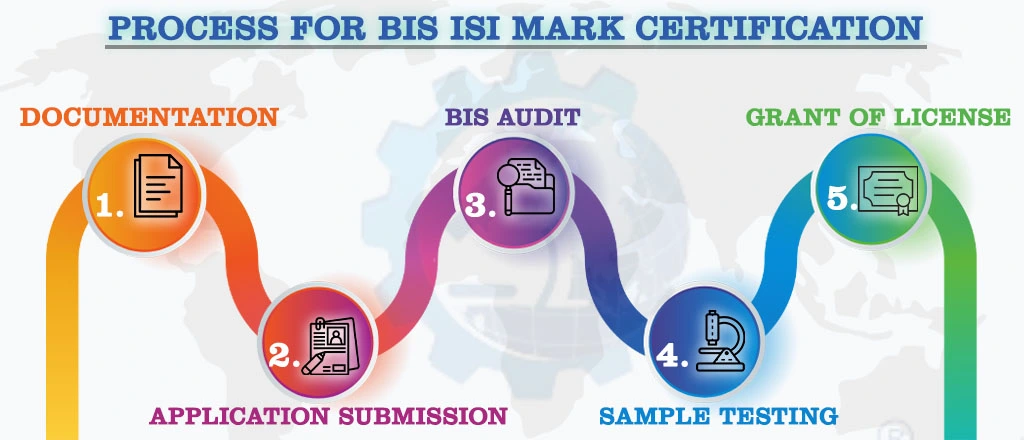

The ISI mark may also be applied to the material. Manufacturers must obtain a BIS license from the Bureau of Indian Standards to use a standard mark (ISI Mark). The Bureau grants a license based on a successful assessment of manufacturing infrastructure, production process, and quality control and testing capabilities during a visit to its manufacturing premises.

NOTE:

For Detailed Information about the Procedure for BIS ISI Certification

Visit :

• ISI Mark Certification for Domestic Manufacturers• ISI Mark Certification for Foreign Manufacturers

Conclusion:

If a product falls under the scope of the BIS Conformity Assessment Scheme, All the manufacturers, importers, and foreign entities must obtain BIS ISI Certification. The Bureau may cancel the License if the product fails to meet certification requirements.

Aleph INDIA has been serving the industry as a single-window operator for all product regulatory compliance. We can assist importers or manufacturers in meeting all criteria for importing or selling a product in the Indian market.

International Audits & Participation

Testimonials

BIS REGISTRATION FOR ELECTRONIC & IT PRODUCT

In the era of globalization, world trade is growing rapidly and henceforth, Manufacturing and Import/Export businesses are also growing drastically...View More

BIS CERTIFICATE FOR FOREIGN MANUFACTURER

The Economy of India-the fastest developing economy on the globe with the capabilities that help it matches up with the biggest international...View More

PRODUCT CERTIFICATION SCHEME (ISI MARK) FOR DOMESTIC MANUFACTURERS

Anything a person buys from food to cars, clothes to electronics, branded to unnamed products there is always a question that wanders in one’s...View More

WIRELESS PLANNING AND COORDINATION (WPC)

WPC: Wireless means communication done from one point to another point without the wires and cables. Electromagnetic waves carry the ...View More

BUREAU OF ENERGY EFFICIENCY (BEE) CERTIFICATE

BEE CERTIFICATE: Energy is the future, and its conservation is the way of the bright future. Everyone claims the environment is important...View More

E-WASTE MANAGEMENT

E-waste is one of the world's fastest-growing trash streams. We currently manufacture almost 50 million tones of it each year...View More

Request a call back.

Would you like to speak to one of our Senior Technical advisers over the phone? Just submit your details and we’ll be in touch shortly. You can also email us if you would prefer.

BIS REGISTRATION FOR ELECTRONIC & IT PRODUCT

In the era of globalization, world trade is growing rapidly and henceforth, Manufacturing and Import/Export businesses are also growing drastically...View More

BIS CERTIFICATE FOR FOREIGN MANUFACTURER

The Economy of India-the fastest developing economy on the globe with the capabilities that help it matches up with the biggest international...View More

PRODUCT CERTIFICATION SCHEME (ISI MARK) FOR DOMESTIC MANUFACTURERS

Anything a person buys from food to cars, clothes to electronics, branded to unnamed products there is always a question that wanders in one’s...View More

WIRELESS PLANNING AND COORDINATION (WPC)

WPC: Wireless means communication done from one point to another point without the wires and cables. Electromagnetic waves carry the ...View More

BUREAU OF ENERGY EFFICIENCY (BEE) CERTIFICATE

BEE CERTIFICATE: Energy is the future, and its conservation is the way of the bright future. Everyone claims the environment is important...View More

E-WASTE MANAGEMENT

E-waste is one of the world's fastest-growing trash streams. We currently manufacture almost 50 million tones of it each year...View More

View All Services

Request a call back.

Would you like to speak to one of our Senior Technical advisers over the phone? Just submit your details and we’ll be in touch shortly. You can also email us if you would prefer.