BIS Certification For Polypropylene (PP) Materials for Moulding and Extrusion IS 10951:2020

As per IS 10951:2020, BIS certification is mandatory for polypropylene (PP) materials used in molding and extrusion processes. This versatile thermoplastic polymer is widely used due to its excellent properties and affordability. In India, Bureau of Indian Standards (BIS) has introduced IS 10951:2020 to ensure the quality of PP materials. Manufacturers are required to obtain BIS certification for PP materials for molding and extrusion, focusing on this standard.

IS 10951:2020 Polypropylene (PP) Materials for Moulding and Extrusion

IS 10951:2020 defines specifications for polypropylene (PP) materials used in molding and extrusion. In molding processes, PP can be molded into complex shapes for automotive components, home appliances, packaging, and consumer goods. In extrusion processes, it can be formed into sheets, films, fibers and profiles for a variety of applications in the packaging, textile, automotive, construction and medical industries. PP materials are recyclable and resistant to moisture, chemicals, and fatigue, making them preferred for applications where strength, versatility, and cost-effectiveness are important.

Key highlights

| Product Name | Polypropylene (PP) Materials for Moulding and Extrusion |

| Applicable Indian Standard | IS 10951: 2020 |

| Applicable Certification Scheme | Product Certification Scheme (ISI Mark Scheme) Scheme 1 - Schedule 2 |

| Compliance Requirement | Mandatory |

| QCO Link | Quality Control Order |

| Scope as per Standard | This standard prescribes the designation system, requirements, methods of sampling and tests for polypropylene (PP) thermoplastics material. It applies to the material ready for normal use in the form of powder, granules or pellets and to materials unmodified or modified by additives, fillers, etc |

Tests

The following are the major tests for Polypropylene (PP) Materials for Moulding and Extrusion.

- Description

- Melt Mass Flow Rate

- Alkalinity as NH3

- Flexural modulus

- Flexural modulus

IS 10951:2020 Additional requirement for Compounded Material Mechanical Properties

- Tensile yield strength

- Elongation at yield

- Tensile strength at break

- Elongation at break

- Charpy impact strength

- Hardness – a) Rockwell, R b) Shore, D

BIS Certification for Polypropylene (PP) Materials IS 10951:2020

It is mandatory for manufacturers of PP materials to obtain ISI/BIS Certification to sell their products in the Indian market. Compliance with IS 10951:2020 ensures consistency, safety and suitability for use in various sectors such as automotive, consumer goods and packaging. Adherence to this standard streamlines production processes, meets regulatory requirements, and enhances competitiveness. IS 10951:2020 encourages innovation and technological advancement in PP material manufacturing by providing a standardized framework for quality assurance and continuous improvement.

BIS Polypropylene (PP) Materials for Moulding and Extrusion IS 10951

IS 10951, part of BIS standards, establishes comprehensive quality parameters for PP materials. BIS certification scheme ensures quality, safety and reliability of products available in the market while protecting consumer interests. BIS certification as per IS 10951:2020 is important to ensure quality, safety and environmental responsibility of PP materials used in molding and extrusion processes. It is essential for manufacturers and businesses in the plastics industry to obtain this certification to excel in the market.

NOTE:

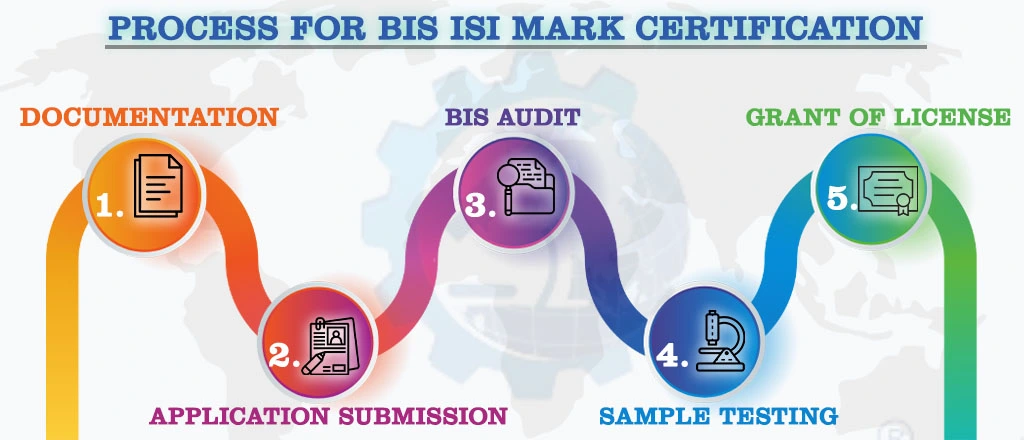

For Detailed Information about the Procedure for BIS ISI Certification, Visit :

Timeline for BIS Certification

The approximate timeline to obtain BIS Certification for copper rods and bars used for general engineering purposes to use ISI mark as Per IS 4171:1983 is given below:

- For Indian Manufacturers (Standard Timeframe – 30 days)

- For Foreign Manufacturers (Standard Timeframe – 180 days)

Conclusion:

Manufacturers and businesses striving to achieve excellence in the plastics industry can greatly benefit from obtaining BIS certification. Aleph India serves as a trusted partner in this journey, providing expertise, guidance and support to streamline the certification process. With BIS certification, businesses can not only ensure compliance with regulatory standards but also gain a competitive edge in the market by offering high quality and eco-friendly PP materials.

International Audits & Participation

Testimonials

BIS REGISTRATION FOR ELECTRONIC & IT PRODUCT

In the era of globalization, world trade is growing rapidly and henceforth, Manufacturing and Import/Export businesses are also growing drastically...View More

BIS CERTIFICATE FOR FOREIGN MANUFACTURER

The Economy of India-the fastest developing economy on the globe with the capabilities that help it matches up with the biggest international...View More

PRODUCT CERTIFICATION SCHEME (ISI MARK) FOR DOMESTIC MANUFACTURERS

Anything a person buys from food to cars, clothes to electronics, branded to unnamed products there is always a question that wanders in one’s...View More

WIRELESS PLANNING AND COORDINATION (WPC)

WPC: Wireless means communication done from one point to another point without the wires and cables. Electromagnetic waves carry the ...View More

BUREAU OF ENERGY EFFICIENCY (BEE) CERTIFICATE

BEE CERTIFICATE: Energy is the future, and its conservation is the way of the bright future. Everyone claims the environment is important...View More

E-WASTE MANAGEMENT

E-waste is one of the world's fastest-growing trash streams. We currently manufacture almost 50 million tones of it each year...View More

View All Services

Request a call back.

Would you like to speak to one of our Senior Technical advisers over the phone? Just submit your details and we’ll be in touch shortly. You can also email us if you would prefer.