BIS CERTIFICATION FOR UPVC PIPES FOR SOIL & WASTE DISCHARGE SYSTEM IS 13592

If you are a manufacturer, a question should always be on your mind while producing goods. What requirements, procedures and testing methodology, and quality control orders need to be followed to produce standard quality products? What is the procedure for BIS certification?

Make sure that your product must follow specified Indian standard for that product. Let's take a closer look at IS 13592:2013 for PVC-U Pipes.

PVC-U pipes for soil and waste discharge system for inside and outside the building, including ventilation and rainwater system is covered under IS 13592:2013. The Bureau of Indian Standards adopted this Indian Standard after the Civil Engineering Division Council approved the draft finalized by the Plastic Piping Systems Sectional Committee.

This standard specifies the requirements for plain and socket end unplasticized polyvinyl chloride (PVC-U) pipes with nominal outside diameters ranging from 40 mm to 315 mm for use in soil and waste discharge systems inside and outside buildings, as well as ventilation, rainwater, and rainwater harvesting. The standard covers pipes with nominal outside diameters of 40, 50, 63, 75, 90, 110, 125, 140, 160, 180, 200, 250, and 315 mm.

TYPES OF PIPES

- Type A: for use in ventilation pipe work and rainwater and rainwater harvesting applications.

- Type B: for use in soil and waste discharge systems.

The material from which the pipes are made shall be primarily polyvinyl chloride. Only those additives necessary to manufacture sound and durable pipes with good surface finish, mechanical strength, and opacity under normal use conditions may be added. When tested as per IS 4669, the composition must be based on PVC resin with a K-value of 64 or greater.

The tests required for this product are:

- Measurement of Outside diameter, wall thickness, length of pipes, and socket

- Visual appearance and Colour test

- Reversion Test

- Stress relief Test

- Vicat softening Temperature Test

- Resistance to sulphuric Acid

- Resistance to External Blows at 0°C

- Water tightness of Joint

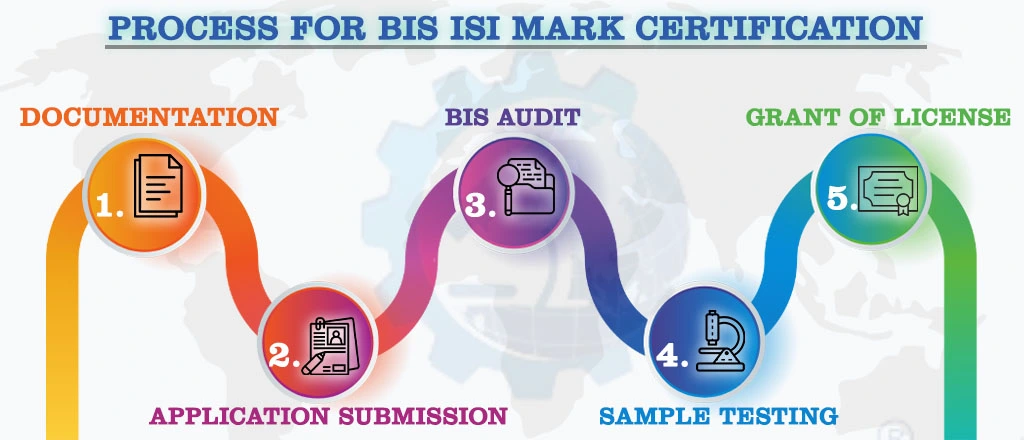

Labeling and marking must be as per the requirements of IS 13592: 2013. Each pipe must also be marked with the Standard Mark (ISI Mark). The manufacturer must obtain a BIS license from the Bureau of Indian Standards to use a standard mark (ISI Mark). The Bureau grants a license based on the successful assessment of a manufacturer's manufacturing infrastructure, production process, quality control and testing capabilities during the visit to its manufacturing premises.

NOTE:

For Detailed Information about the Procedure for BIS ISI Certification,

Visit :

ISI Mark Certification for Domestic ManufacturersISI Mark Certification for Foreign Manufacturers

Conclusion:

If a product falls under the scope of the BIS Conformity Assessment Scheme, All the manufacturers, importers, and foreign entities must obtain BIS ISI Certification. The Bureau may cancel the License if the product fails to meet certification requirements.

Aleph INDIA has been serving the industry as a single-window operator for all product regulatory compliance. We can assist importers or manufacturers in meeting all criteria for importing or selling a product in the Indian market.

International Audits & Participation

Testimonials

BIS REGISTRATION FOR ELECTRONIC & IT PRODUCT

In the era of globalization, world trade is growing rapidly and henceforth, Manufacturing and Import/Export businesses are also growing drastically...View More

BIS CERTIFICATE FOR FOREIGN MANUFACTURER

The Economy of India-the fastest developing economy on the globe with the capabilities that help it matches up with the biggest international...View More

PRODUCT CERTIFICATION SCHEME (ISI MARK) FOR DOMESTIC MANUFACTURERS

Anything a person buys from food to cars, clothes to electronics, branded to unnamed products there is always a question that wanders in one’s...View More

WIRELESS PLANNING AND COORDINATION (WPC)

WPC: Wireless means communication done from one point to another point without the wires and cables. Electromagnetic waves carry the ...View More

BUREAU OF ENERGY EFFICIENCY (BEE) CERTIFICATE

BEE CERTIFICATE: Energy is the future, and its conservation is the way of the bright future. Everyone claims the environment is important...View More

E-WASTE MANAGEMENT

E-waste is one of the world's fastest-growing trash streams. We currently manufacture almost 50 million tones of it each year...View More

Request a call back.

Would you like to speak to one of our Senior Technical advisers over the phone? Just submit your details and we’ll be in touch shortly. You can also email us if you would prefer.

BIS REGISTRATION FOR ELECTRONIC & IT PRODUCT

In the era of globalization, world trade is growing rapidly and henceforth, Manufacturing and Import/Export businesses are also growing drastically...View More

BIS CERTIFICATE FOR FOREIGN MANUFACTURER

The Economy of India-the fastest developing economy on the globe with the capabilities that help it matches up with the biggest international...View More

PRODUCT CERTIFICATION SCHEME (ISI MARK) FOR DOMESTIC MANUFACTURERS

Anything a person buys from food to cars, clothes to electronics, branded to unnamed products there is always a question that wanders in one’s...View More

WIRELESS PLANNING AND COORDINATION (WPC)

WPC: Wireless means communication done from one point to another point without the wires and cables. Electromagnetic waves carry the ...View More

BUREAU OF ENERGY EFFICIENCY (BEE) CERTIFICATE

BEE CERTIFICATE: Energy is the future, and its conservation is the way of the bright future. Everyone claims the environment is important...View More

E-WASTE MANAGEMENT

E-waste is one of the world's fastest-growing trash streams. We currently manufacture almost 50 million tones of it each year...View More

View All Services

Request a call back.

Would you like to speak to one of our Senior Technical advisers over the phone? Just submit your details and we’ll be in touch shortly. You can also email us if you would prefer.