BIS Certification Aluminium alloy forging stock and forgings (Alloy 24345) for aerospace applications IS 7902:2001

As per IS 7902:2001, BIS certification is mandatory for aluminium alloy forged stocks and forgings (alloy 24345) used in aerospace applications. This standard ensures that materials required for strong, lightweight and durable applications, such as industrial machinery and aircraft parts, meet stringent quality requirements. The mechanical properties of aluminium alloys are enhanced through forging, making them important to the aerospace sector in creating high-performing and safe aeroplanes and spacecraft.

Under the Directive, all items related to aluminium and aluminium alloy products must conform to Indian Standard 7902:2001, specifically "Aluminium alloy forged stocks and forgings (alloy 24345) for aerospace applications."

Key highlights

| Product Name | Aluminium alloy forging stock and forgings for aircraft purposes (Alloy 24345) |

| Applicable Indian Standard | IS 7902: 2001 |

| Applicable Certification Scheme | Product Certification Scheme (ISI Mark Scheme) Scheme 1 - Schedule 2 |

| Compliance Requirement | Mandatory |

| QCO Link | Quality Control Order |

| Scope as per Standard | This standard covers the requirements of aluminium - copper -magnesium - silicon - manganese alloy (Alloy 24345) forging stocks (billets, bars, rods, sections) and forgings. The material is intended primarily for aircraft structural parts requiring moderate strength. |

Tests

The following are the major tests for Aluminium alloy forging stock and forgings for aircraft purposes (Alloy 24345):

- Freedom from defects

- Chemical Composition

- Heat treatment

- Tensile Test

- Hardness

- Dimensions and Tolerances

- Manufacture (raw material)

- Ultrasonic Test

- Dye penetrant test

- Macro and Micro Examination

Compliance with IS 7902:2001 requires that all aluminium alloy forged stocks and forgings (alloy 24345) intended for aircraft applications be included in the ISI certification scheme. The standard covers specifications for aluminium, copper, magnesium, silicon and manganese alloy forging stocks (billets, bars, rods, sections) on materials designed primarily for medium strength structural sections of aircraft. Is concentrated.

The absence of ISI mark makes these products ineligible for marketing, import or export in the Indian consumer market. This underlines the importance of adhering to quality standards, ensuring that aluminium alloy forging stocks and forgings meet specified criteria for aerospace applications, contributing to the safety and efficiency of aircraft manufacturing.

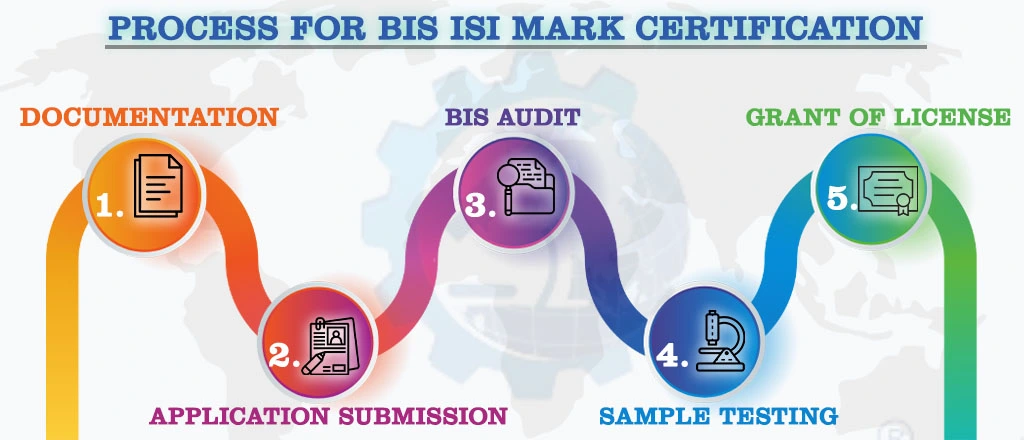

BIS Certification Process

Obtaining a BIS license involves a thorough assessment of manufacturing infrastructure, quality control capabilities, testing facilities, and production processes. This comprehensive evaluation ensures that the products not only comply with regulations but are also safe and reliable for consumers.

NOTE:

For Detailed Information about the Procedure for BIS ISI Certification, Visit :

Timeline for BIS Certification

The approximate timeline to obtain BIS Certification for Aluminium alloy forging stock and forgings for aircraft purposes (Alloy 24345). to use ISI mark as Per IS 7902:2001 is given below:

- For Indian Manufacturers (Standard Timeframe – 30 days)

- For Foreign Manufacturers (Standard Timeframe – 180 days)

Conclusion:

The implementation of the Aluminium alloy forging stock and forgings for aircraft purposes (Alloy 24345) (Quality Control) Order, 2023, is ushering in a transformative era for the market of Aluminium alloy forging stock and forgings for aircraft purposes (Alloy 24345) in India. Manufacturers, by embracing these guidelines and securing BIS certification, are not merely complying with regulations; they are setting new benchmarks for excellence in the industry. Opting for BIS-certified Aluminium alloy forging stock and forgings for aircraft purposes (Alloy 24345) signifies more than a product purchase; it represents a commitment to dependability, superior quality, and safety.

BIS certification for Aluminium alloy forging stock and forgings for aircraft purposes (Alloy 24345) goes beyond meeting regulatory checkboxes, assuring the highest performance standards in these products. In an era where quality takes precedence, choosing BIS-certified Aluminium alloy forging stock and forgings for aircraft purposes (Alloy 24345) guarantees a product that is not only dependable but also of the finest quality.

In this landscape of evolving standards, Aleph INDIA stands as a leading BIS consultant in India, dedicated to assisting manufacturers and importers in obtaining BIS licenses for their products. With a commitment to excellence, Aleph INDIA ensures that your products not only meet but exceed the required quality benchmarks. Aleph INDIA has been serving the industry as a single-window operator for all product regulatory compliance. We can assist importers or manufacturers in meeting all criteria for importing or selling a product in the Indian market.

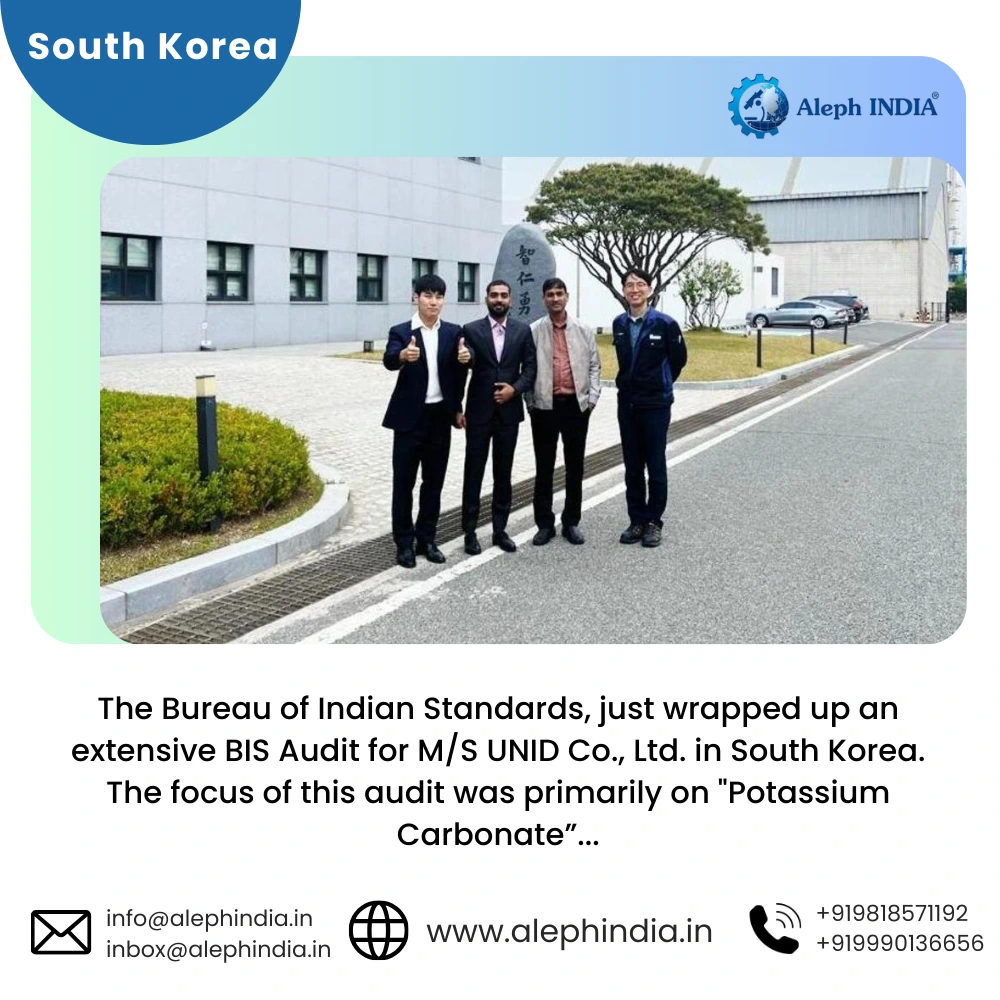

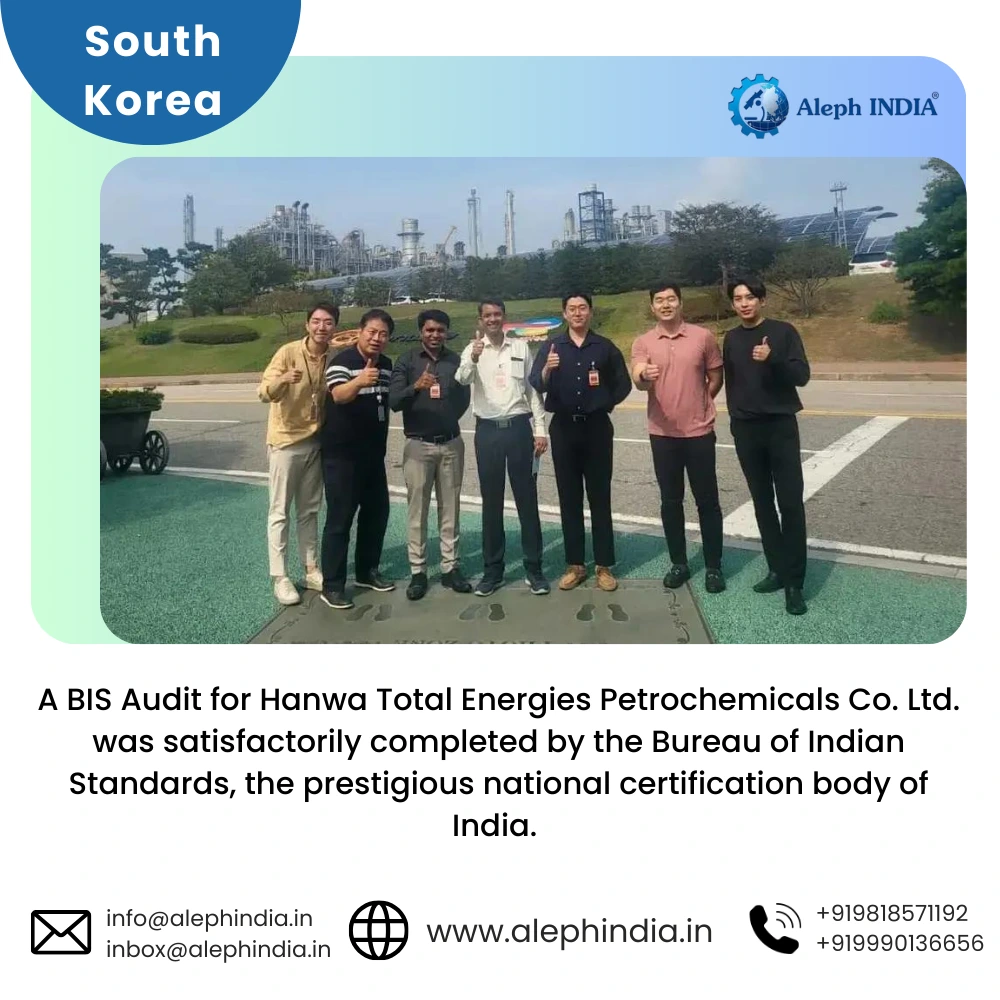

International Audits & Participation

Testimonials

BIS REGISTRATION FOR ELECTRONIC & IT PRODUCT

In the era of globalization, world trade is growing rapidly and henceforth, Manufacturing and Import/Export businesses are also growing drastically...View More

BIS CERTIFICATE FOR FOREIGN MANUFACTURER

The Economy of India-the fastest developing economy on the globe with the capabilities that help it matches up with the biggest international...View More

PRODUCT CERTIFICATION SCHEME (ISI MARK) FOR DOMESTIC MANUFACTURERS

Anything a person buys from food to cars, clothes to electronics, branded to unnamed products there is always a question that wanders in one’s...View More

WIRELESS PLANNING AND COORDINATION (WPC)

WPC: Wireless means communication done from one point to another point without the wires and cables. Electromagnetic waves carry the ...View More

BUREAU OF ENERGY EFFICIENCY (BEE) CERTIFICATE

BEE CERTIFICATE: Energy is the future, and its conservation is the way of the bright future. Everyone claims the environment is important...View More

E-WASTE MANAGEMENT

E-waste is one of the world's fastest-growing trash streams. We currently manufacture almost 50 million tones of it each year...View More

View All Services

Request a call back.

Would you like to speak to one of our Senior Technical advisers over the phone? Just submit your details and we’ll be in touch shortly. You can also email us if you would prefer.