BIS Certification for Tower Bolts - Non-ferrous metals IS 204 (Part 2): 1992

In today's high-speed manufacturing environment, ensuring product quality is not merely a choice but an absolute necessity. The recent Bolts, Nuts, and Fasteners (Quality Control) Order, 2023, issued by the Ministry of Commerce & Industry, Central Government in consultation with the Bureau of Indian Standards (BIS), has ushered in new requirements for the production and sale of Tower Bolts made of non-ferrous metals, aligning with IS 204 (Part 2): 1992.

Tower bolts made of non-ferrous metals serve as essential hardware components in various applications, particularly within the construction and building industry. Their primary purpose is to secure double doors, providing a reliable and efficient means of latching and bolting. These bolts play a crucial role in ensuring the stability and security of doors, making them widely utilized in residential, commercial, and industrial settings. With their sturdy construction and durable materials, tower bolts made of non-ferrous metals contribute to the overall safety and functionality of doors, making them a vital component in door hardware systems.

Key highlights

| Product Name | Tower Bolts- Non-ferrous metals |

| Applicable Indian Standard | 204 (Part 2): 1992 |

| Applicable Certification Scheme | Product Certification Scheme (ISI Mark Scheme) Scheme 1 - Schedule 2 |

| Compliance Requirement | Mandatory |

| QCO Link | Quality Control Order |

The Essence of Standardized Quality

Standardized quality products are no longer a mere preference; they are imperative for survival in a competitive market. The BIS license and the ISI Mark have become essential for manufacturers aiming to thrive in the Indian market.

Recognizing the significance of upholding high standards, the Central Government has mandated that Tower Bolts made of non-ferrous metals must adhere to the prescribed Indian Standard, as per IS 204 (Part 2): 1992. This ensures that these essential components meet stringent quality benchmarks.

Understanding the Standards: IS 204 (Part 2): 1992

Manufacturers can use the Standard Mark in accordance with IS 204 (Part 2): 1992 only with a BIS license. Labeling and marking must strictly adhere to IS 204 (Part 2): 1992 requirements, and packaging for Tower Bolts made of non-ferrous metals must align with IS IS 204 (Part 2): 1992. Every production meeting these Indian Standards and approved by the license must bear the prestigious Standard ISI Mark.

To obtain the license, manufacturers must secure a BIS license for Tower Bolts made of non-ferrous metals from the Bureau of Indian Standards. The Bureau grants this license after a comprehensive assessment of manufacturing infrastructure, quality control, testing capabilities, and the overall production process. This BIS license is crucial to ensure the safety and reliability of Tower Bolts made of non-ferrous metals for consumers.

Quality Assurance Through Rigorous Testing

Maintaining a dedicated laboratory for various tests specified in the standard is fundamental. Rigorous testing, following the outlined methods, ensures that the Tower Bolts - Non-ferrous metals meet the required quality and safety standards.

The following are the major tests for Tower Bolts - Non - ferrous metals are:

- Dimensions and Tolerances

- Tensile test

- Proof load test

- Hardness test

- Yield strength test

- Finished test

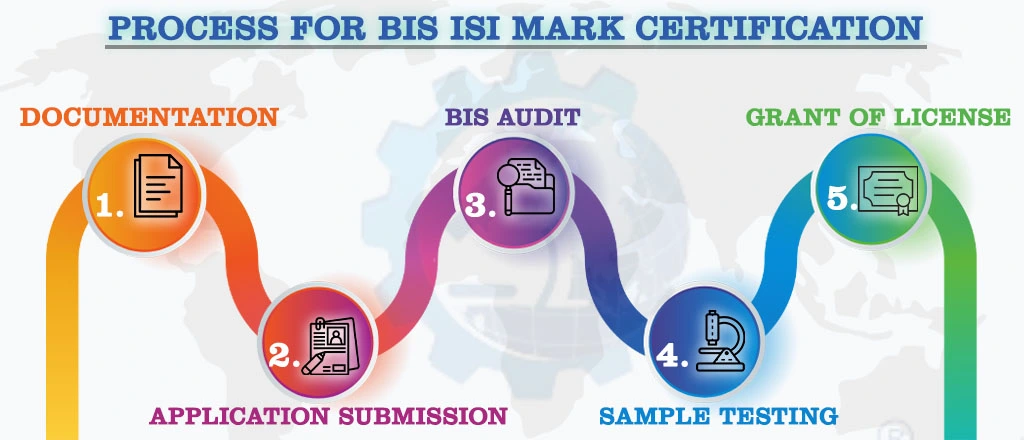

BIS Certification Process

Obtaining a BIS license involves a thorough assessment of manufacturing infrastructure, quality control capabilities, testing facilities, and production processes. This comprehensive evaluation ensures that the products not only comply with regulations but are also safe and reliable for consumers.

NOTE:

For Detailed Information about the Procedure for BIS ISI Certification, Visit :

Conclusion:

A new chapter in the history of the manufacture and distribution of high-strength structural bolts in the Indian market begins with the implementation of the Bolts, Nuts and Fasteners (Quality Control) Order, 2023. By adopting these standards and obtaining BIS certification, manufacturers are doing more than just complying with regulations; they are driving industry excellence and giving customers confidence in the product's quality, safety, and dependability.

BIS certification for High Strength Structural Bolts is a commitment to delivering excellence in every product in an era where quality is most important. It goes beyond simply checking regulatory boxes.

In this landscape of evolving standards, Aleph INDIA stands as a leading BIS consultant in India, dedicated to assisting manufacturers and importers in obtaining BIS licenses for their products. With a commitment to excellence, Aleph INDIA ensures that your products not only meet but exceed the required quality benchmarks. Aleph INDIA has been serving the industry as a single-window operator for all product regulatory compliance. We can assist importers or manufacturers in meeting all criteria for importing or selling a product in the Indian market.

International Audits & Participation

Testimonials

BIS REGISTRATION FOR ELECTRONIC & IT PRODUCT

In the era of globalization, world trade is growing rapidly and henceforth, Manufacturing and Import/Export businesses are also growing drastically...View More

BIS CERTIFICATE FOR FOREIGN MANUFACTURER

The Economy of India-the fastest developing economy on the globe with the capabilities that help it matches up with the biggest international...View More

PRODUCT CERTIFICATION SCHEME (ISI MARK) FOR DOMESTIC MANUFACTURERS

Anything a person buys from food to cars, clothes to electronics, branded to unnamed products there is always a question that wanders in one’s...View More

WIRELESS PLANNING AND COORDINATION (WPC)

WPC: Wireless means communication done from one point to another point without the wires and cables. Electromagnetic waves carry the ...View More

BUREAU OF ENERGY EFFICIENCY (BEE) CERTIFICATE

BEE CERTIFICATE: Energy is the future, and its conservation is the way of the bright future. Everyone claims the environment is important...View More

E-WASTE MANAGEMENT

E-waste is one of the world's fastest-growing trash streams. We currently manufacture almost 50 million tones of it each year...View More

View All Services

Request a call back.

Would you like to speak to one of our Senior Technical advisers over the phone? Just submit your details and we’ll be in touch shortly. You can also email us if you would prefer.