- HOME

- ABOUT US

- SERVICES

-

LICENCE & CERTIFICATION

- BIS (ISI MARK) FOR FOREIGN MANUFACTURERS

- DOMESTIC PRODUCT CERTIFICATION (ISI MARK)

- BIS CERTIFICATE OF CONFORMITY (CoC)

- BIS HALLMARKING

- BIS LICENCE FOR TOYS

- REACH CERTIFICATION (GLOBAL)

- COSMETIC REGISTRATION (CDSCO)

- LABORATORY RECOGNITION SCHEME (LRS)

- WORLD MANUFACTURER IDENTIFIER (WMI) CODE

- ECO MARK

- TAC APPROVAL FOR AUTOMOBILE

- DRUG LICENCE

- PESO CERTIFICATION

-

REGISTRATION

- BIS (CRS) REGISTRATION FOR ELECTRONIC PRODUCT

- WPC-ETA APPROVAL

- BEE CERTIFICATION

- E-WASTE MANAGEMENT (EPR)

- EPR REGISTRATION FOR PLASTIC WASTE MANAGEMENT

- EPR REGISTRATION FOR BATTERY WASTE MANAGEMENT

- LEGAL METROLOGY (LMPC)

- TEC APPROVAL

- CE CERTIFICATION

- UL CERTIFICATION

- ROHS LICENCE

- DRONE REGISTRATION

- MOEF LICENCE

-

AUXILIARY

- STANDARDIZATION (SCIENTIFIC) DIVISION

- TRAINING SERVICES (NATIONAL & INTERNATIONAL)

- IMPORT/EXPORT LICENCE

- FSSAI CERTIFICATION

- MSME/SSI/NSIC REGISTRATION

- ISO REGISTRATION

- BRAND REPRESENTATION

- LABORATORY EQUIPMENT AND SETUP

- TRADEMARK REGISTRATION

- MAKE IN INDIA SUPPORT

- AG-MARK LICENCE

- THIRD PARTY INSPECTION AND MONITORING SERVICES

-

- PORTFOLIO

- UPDATES

- CONTACT

- LOGIN

BIS ISI MARK CERTIFICATION FOR DOMESTIC MANUFACTURERS

[ Table Of Content ]

- What is BIS Certification?

- Why BIS Certificate?

- What is ISI Mark?

- Difference between BIS and ISI Mark

- Basic Requirements for BIS Certification

- Benefits of BIS Certification (ISI Mark Certificate)

- List of Products Under ISI Certification

- BIS ISI Certification Procedure

- What is BIS Certification Cost for ISI Mark Scheme?

- Documents Requirement to Get ISI Certificate in India

- Conclusion

- Products under BIS certification scheme

- Frequently Asked Questions (FAQ)

Let's first look at what is BIS Certification?

The Bureau of Indian Standards (BIS) is the National Certification body of India that issues BIS licenses to the manufacturers and importers for various products comes under BIS voluntary or mandatory certification schemes. BIS certification is a third-party assurance of the product's quality, the consumer's security, and the trustworthiness of BIS. The government of India established the Bureau of Indian Standards under the BIS Act, 1986, under the supervision of the Indian Ministry of Consumer Affairs, Food, and Public Distribution.

"BIS certification, a badge of honor and trust; Benchmark of excellence, for products you must;

Business growth, in India's vast domain;

Building a reputation, that will surely sustain;

And seize success, as you ascertain."

Being a national agency BIS has responsibility for numerous certifications for maintaining the quality standard of the products in the Indian market. The Bureau of Indian Standards grants BIS certification to companies for products that meet quality standards under the Product Certification Scheme. Furthermore, this procedure conducted through the Bureau of India Standards helps businesses to establish a brand image for their product within the industry. Over the years, the BIS has been the second name in terms of authenticity and quality. After BIS Certification, producers can use their standard marking, on their BIS-certified products.

BIS certification is a process of certifying that a product conforms to a certain Indian standard and is therefore considered safe for use in the Indian market. BIS certification is mandatory for certain products listed in mandatory Product Certification Scheme of BIS, to be sold in India. Obtaining BIS certification requires passing various tests and inspections to ensure the product meets the relevant Indian standards.

Why BIS Certificate?

Whatever a consumer buys, from food to cars, from clothes to electronics, from branded items to non-branded ones, there is always a doubt in mind on how to determine whether they can trust the product or company. Are there any criteria using which one can determine the quality, luxury, or grade of the product that is to be purchased? If there are some parameters, then who decides these? How will your customers know they can trust your brand and its products? This is where BIS Certification comes into play.

BIS Certification (ISI Mark) in India is considered as a mark of trust for the buyers. A BIS Certificate from the Bureau of Indian Standards allows the manufacturers to assure the consumers about product quality, consumer safety, and trustworthiness. BIS Certification Scheme is a voluntary scheme; however, some products are covered under the mandatory certification scheme of BIS.

What is ISI Mark?

ISI is an acronym for Indian Standards Institute, the National Standards body renamed Bureau of Indian Standards in 1987. The ISI Mark is the official mark given to producers by the Bureau of Indian Standards for diverse items. This ISI Mark has been considered a symbol of quality, safety, and trust since 1955. The ISI mark has been used as conformity marking for industrial products. It assures that the product complies with the Indian standards (IS) developed by India's national standard organization, the Bureau of Indian Standards (BIS).

ISI Mark Registration is obtaining the ISI mark for any product that complies with Indian Standards. Various electrical appliances require mandatory ISI marks, such as Electric Iron, Room Heaters, Room AC, Electric Stoves, Freezers, Electric cables, and other products like UPVC Pipes, Rubber & Leather Footwears, Composite Cements, various acids, etc.

Difference between BIS and ISI Mark

BIS, as a quality management organization, is responsible for providing quality certification as well as ensuring the quality, stability, and reliability of goods for end users. Whereas ISI Mark is a standard mark awarded by the Bureau of Indian Standards for the conformity of the product as per Indian standards. The ISI mark on the product indicates that a product matches the quality standard set by the BIS. Under the product certification scheme, BIS gives manufacturers a license to use the standard Mark (ISI Mark) on products that conform to applicable Indian standards. ISI Mark consisting of the Licence number as 'CM/L-XXXXXXXXXX' at the bottom of the ISI Mark and the Indian standard number at the top of the above ISI Mark.

Basic Requirements for BIS Certification

The following are the basic requirements for obtaining a BIS licence, as listed below.

- The product must meet the Indian Standard Specification criteria.

- BIS license is only given to the factory (manufacturer of finished products), not to the Distributor/Retailer.

- If a manufacturer has multiple factories, each of which is located at a distinct geographical address, the business must file a separate application for each product and factory location.

- The laboratory should be fully equipped with product testing equipment as well as qualified quality control personnel to test the product in accordance with the applicable ISS.

- All production machinery and testing facilities should be located on the factory premises as per ISS norms and respective SIT.

- All procedures should be completed in the same factory, from receiving raw materials to final packing. If any out-sourcing is required, clearance from the Bureau may be requested.

- The technical guidelines are available for all products covered under the Product Certification Scheme as 'Product Manuals'. Product manuals include sampling guidelines, a list of test equipment, a Scheme of Inspection and Testing (SIT), a description of scope etc. Applicant can refer to this Product Manual for BIS ISI Certification to prepare for the audit and application submission so that chances of rejection can be avoided.

Benefits of BIS Certification (ISI Mark Certificate)

With ISI Mark Certification, companies and their products simply unlock the following motives:

- ISI Mark Certificate allows the manufacturers uninterrupted manufacturing and selling of their products in every part of India.

- BIS certification allows the manufacturers to use the Standard Mark i.e, ISI Mark on their manufactured products that are in the mandatory certification scheme. Manufacturing these products without an ISI Mark could result in a substantial fine, imprisonment or both.

- ISI Mark on any product ensures consumer's safety and health and develops trust.

- BIS certified product ensures high quality and consumer satisfaction, which increases revenue.

Do you know that ISI Mark Certification is mandatory in India for more than 150 products? Even though it is voluntary to get BIS license, the BIS made it compulsory to attain the certificate on certain products to make sure the safety of the consumers from counterfeits and fake merchandise.

Also Read

BIS Registration for Electronic and IT ProductsISI Mark Certification for Foreign Manufacturers

List of Products Under ISI Certification:

- Food-related products

- Glass & Glassware

- Cylinders and regulators

- Building Materials

- Primary Batteries

- Rubber

- Oil pressure stoves

- Wire & Cables

- Medical equipment

- Shoes & Leather Products

- Cement

- Automotive

- Capacitors

- Aluminum

- Chemicals and fertilizers

- Wheel Rim & Valves

- Household electrical goods

- Steel Products

- Electric motors and transformers

Check the complete list of products that require mandatory BIS Certification to use ISI Mark under Product Certification Scheme:

Type of procedure

BIS ISI Certification Process for Indian Manufacturers

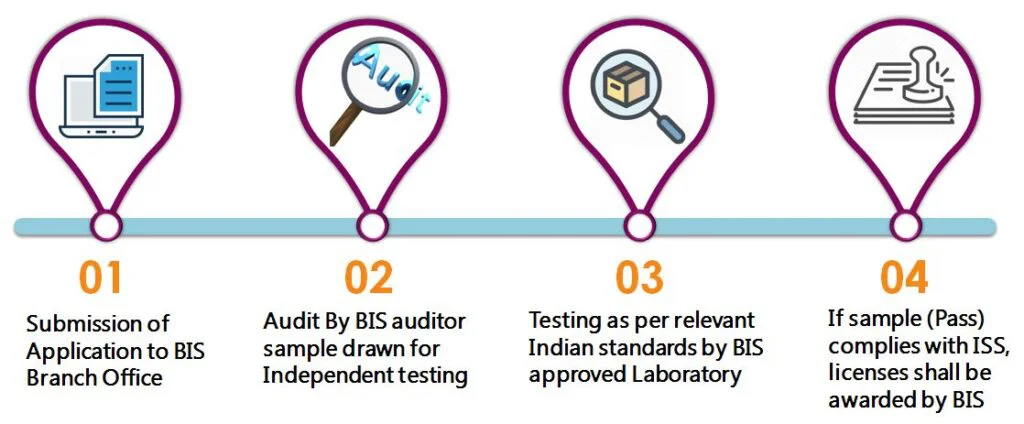

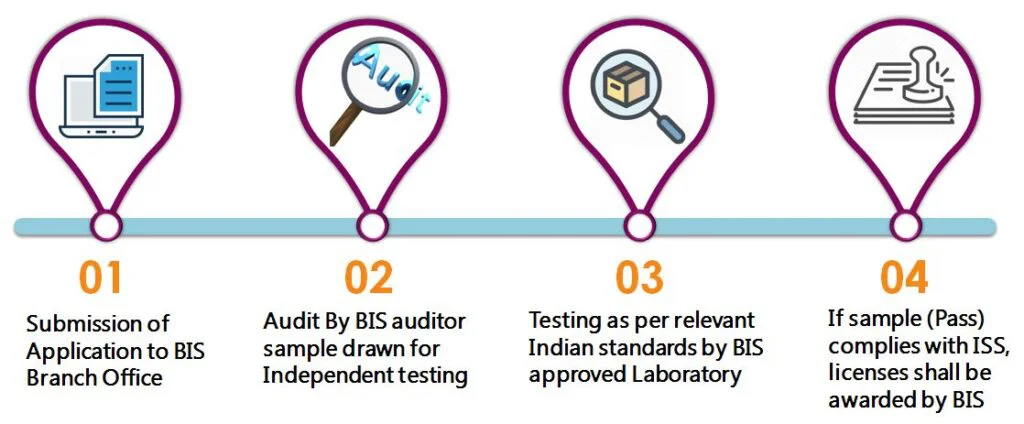

In this section we will discuss about "How to apply for ISI Mark?" or we can say "How to get ISI Certification for your Product?" The ISI Mark Certification process in India involves the following steps:

- Relevant Product Code selection

- ISI Mark Registration online Aplication form fill up with the required documents

- Factory audit by BIS authorized auditor

- Sample Report submission by BIS authorized laboratory

- Grant of licence by BIS Authority

Further the BIS certification can be obtained following two different procedures

- Normal Procedure (takes 60 - 65 days)

- Simplified Procedure (takes 35 40 days)

Normal Procedure

The following steps will take place under normal procedure:

- First, the applying party has to prepare for the BIS Certificate requirements, especially setting in-house labs and preparing products as per Indian Standards with other required documents.

- Afterward, the BIS official will conduct an inspection process of products along with the factory/industry.

- Once the inspection gets completed, the sealed samples of the goods are further sent for testing at the BIS approved laboratories.

- If the product passes all the test parameters, then only it gets approved from the BIS, and the authority issues the BIS certificate for Indian Manufacturers in 60 to 65 days from the submission of the application.

Simplified Procedure

This procedure of BIS Certification is much faster than compared to the regular procedure.

- Initially, the applying party submits the report of the samples already tested and approved by BIS as per Indian Standard.

- Afterward, the applicant has to submit an BIS online registration application and BIS Certification Cost along with other required sets of documents.

- During scrutiny of application documents, the BIS official will conduct an inspection process of products along with the factory/industry.

- Once the inspection gets completed, the sealed samples of the goods are further sent for testing at the BIS approved laboratories.

- Then, if verified and approved according to the commended standards, the certificate is granted by the BIS within 35 to 40 days of application.

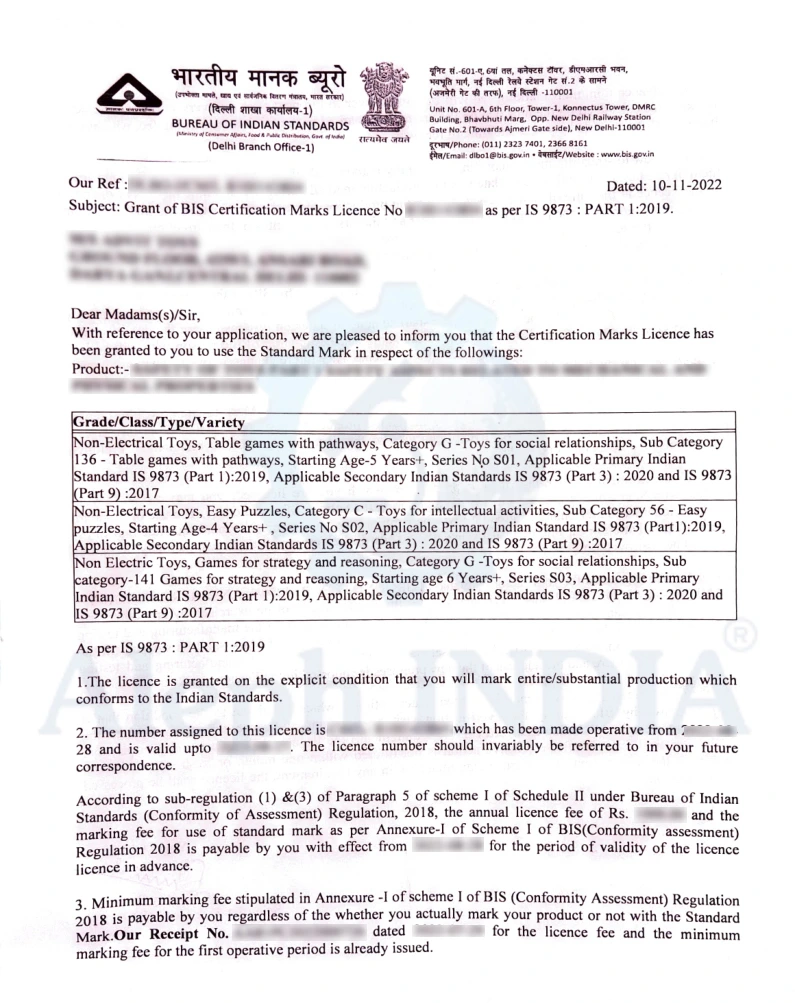

Sample of a Grant licence for ISI Mark

WHAT IS BIS CERTIFICATION COST FOR ISI MARK SCHEME?

BIS CERTIFICATION COST FOR ISI MARK

The BIS certification cost/fee structure for new registration is given below. The same applies to the renewal of Old Accredited BIS certificates as well.

| No. | Type of Fees/Charges | Amount | Remarks |

| 1 | APPLICATION FEE | INR 1000/- | To be paid in BIS account. |

| 2 | AUDIT CHARGES | INR 7000/- | To be paid in BIS account. |

| 3 | SAMPLE TEST FEE | As Applicable | To be paid in BIS account. (Sample test fee may vary as per products and laboratory) |

| 4 | LICENSE FEE | INR 1000/- | To be paid in BIS account. |

| 5 | MINIMUM ADVANCE MARKING FEE | As per actual | To be paid in BIS account. (Marking fee is different as per IS Standard) |

Apart from the above, BIS certification also incurs product testing charges. It also requires investment in factory premises, especially in the installation of testing machinery for in-house factory test labs which is a crucial part of the entire BIS Certification process.

Documents Required to Get BIS ISI Mark Certificate in India

Documentations requirement is very specific and generic for the BIS Certification application which includes:

- Laboratory Test Reports as per Product Standard

- Factory Registration Documents

- Manufacturing process flow chart

- In-house Testing Facilities

- Details of Authorized Signatory and other related documents.

Conclusion

Are you a manufacturer looking for a BIS ISI Mark consultant in Delhi, India, to get a BIS license for your product?

Aleph India is one of the top ISI Mark consultant in Delhi providing ISI Mark certification services in India and overseas. Since 2013, we have been offering a one-stop solution for product certification for both Indian and foreign manufacturers. We assist manufacturers in obtaining the ISI Mark for various products, including Aluminium foils, Safety Glasses, FRK blending machines, PVC Insulated cables, toys, helmets and other products covered under Product Certification Scheme. Our goal is to help manufacturers get their products tested and verified so they can receive the ISI Mark in India under the BIS Conformity Assessment Scheme. Throughout the process, we provide valuable guidance and support. Please note that the Bureau can revoke the license if any of the license conditions are violated, as per Regulation 11 of BIS (Conformity Assessment) Regulations, 2018.

Aleph India provides a wide range of technical and regulatory compliance services, such as product certification (BIS Registration under CRS, FMCS, BIS ISI certification, WPC etc.), product testing, technical training for quality control, auditing of manufacturing and laboratory units, etc., enables industries to reach higher productivity and quality standards.

PRODUCTS UNDER BIS CERTIFICATION SCHEME

As of now, These are the following products which needs BIS Certificate in India under mandatory certification scheme to Manufacture/Import and sell these products in the INDIAN market. Click on below listed products for more information. Call us at 0-804-803-68-69/91-9990136656 or Email at inbox@alephindia.in for more details.

Frequently asked questions (FAQ)

- Ensure best quality products as per Indian standards.

- Ensures consumers safety and health.

- Develops consumer's trust in products.

- Promotes import and export substitutes.

- To determine whether the government issued a certificate, visit the Manakonline site.

- After that, you will see the "Search a License" page displayed beneath the Conformity Assessment option.

- After clicking "Search a License," enter the license number, registration number and the company's name will be added.

- Once you have entered the necessary information, a report will be produced.

The Bureau of Indian Standards operates a Product Certification Scheme to grant a license to manufacturers to use the Standard Mark (ISI Mark) on their product. The BIS Conformity Assessment Schemes provides confidence to consumers about the Quality, Safety, and Reliability of products and ensures Consumer Protection

BIS certification is a voluntary scheme. However, the Central Government has made it mandatory for the manufacturers of certain products to ensure the consumer's safety. Manufacturers of Electrical appliances, kitchen appliances, LPG valves, LPG cylinders, cement, food products, automotive tires, etc., require a mandatory ISI mark to sell their products in India. If your product is on that list, it is compulsory for you to get a BIS license.

Documents required for BIS Certification include a Business certificate, Lab test report, List of machinery and product, Manufacturing flow chart, AIR nomination form ( in case of foreign manufacturer), etc.

The process of BIS certifications involves:- Filling the Application form with the required documents. Factory audit by BIS authorized auditor. Sample Report submission by BIS authorized laboratory. Grant of license by BIS Authority.

Application fee for grant of registration: ₹1000/- (ii) Processing fee of ₹ 25000/- (including one test report). For additional test reports included with the application, additional processing fee of ₹10000/- per test report will be charged.

Benefits of BIS Certification are:

To check your BIS Certificate in India, you have to follow the following steps:

The BIS certification Scheme is voluntary; the number of products is made compulsory by the Government of India on various considerations like public interest protection of human, animal, or plant health. All products are covered under the product certification scheme except electronics and IT products.

To obtain a BIS licence, the manufacturer must have the necessary manufacturing infrastructure, appropriate process controls, quality control, and testing capabilities for the product in accordance with relevant Indian Standards (ISS). The product must also meet all of the requirements outlined in the ISS.

The Bureau of Indian Standards grants a licence to the manufacturer according to Scheme-I of Schedule-II of the BIS (Conformity Assessment) Regulations, 2018, to use the standard mark (ISI Mark) on the product.

घरेलू निर्माताओं के लिए उत्पाद प्रमाणन योजना (आईएसआई (ISI) मार्क)

BIS प्रमाणन (Certification) (BIS Certification) क्या है?

BIS सर्टिफिकेशन: BIS अधिनियम, 1986 के तहत, भारत सरकार ने भारतीय उपभोक्ता संरक्षण, खाद्य और सार्वजनिक वितरण मंत्रालय के तहत राष्ट्रीय भारतीय प्रमाणन (Certification) निकाय यानी भारतीय मानक ब्यूरो (BIS) की स्थापना की। भारतीय मानक ब्यूरो सबसे बड़ा भारतीय प्रमाणन (Certification) निकाय है जो उत्पादों के गुणवत्ता मानकों के प्रबंधन और प्रमुख प्रमाणपत्रों के लिए जिम्मेदार है।

BIS कंपनियों को उनके उत्पादों के मानकों की पुष्टि करने के बाद BIS प्रमाणन (Certification) देता है। इसके अतिरिक्त, भारतीय मानक प्रमाणन (Certification) ब्यूरो द्वारा संचालित यह प्रक्रिया कंपनियों को उद्योग में एक प्रतिष्ठित ब्रांड बनाने में मदद करती है। भारत में BIS प्रमाणन (Certification) वाले उत्पाद पर ISI मार्क अनिवार्य है।

BIS प्रमाणपत्र (BIS Certificate) की आवश्यकता क्यों है?

कोई भी व्यक्ति भोजन से लेकर कार, कपड़े से लेकर इलेक्ट्रॉनिक्स उत्पादों तक जो कुछ भी खरीदता है, उसके मन में हमेशा एक सवाल रहता है कि कैसे पता चले कि वह उत्पाद अच्छी गुणवत्ता और भरोसेमंद है या नहीं। क्या कोई पैरामीटर हैं जिनके द्वारा खरीदे जाने वाले वस्तु की गुणवत्ता या ग्रेड का अनुमान लगाया जा सकता है, और यदि किसी प्रकार के पैरामीटर हैं तो इन मापदंडों को कौन तय करता है?

आपके ग्राहक को कैसे पता चलेगा कि वे आपके ब्रांड और उसके उत्पादों पर भरोसा कर सकते हैं? यहीं से BIS प्रमाणन (Certification) काम आता है। भारत में BIS प्रमाणन (Certification) को खरीदारों के लिए भरोसे का प्रतीक माना जाता है।

BIS प्रमाणन (Certification) के लिए बुनियादी मानदंड:

BIS लाइसेंस (BIS Licence) प्राप्त करने के लिए निम्नलिखित बुनियादी आवश्यकताएं हैं:

- उत्पाद को भारतीय मानक विशिष्टता मानदंडों को पूरा करना चाहिए।

- BIS लाइसेंस केवल उत्पादों के निर्माता को दिया जाता है, वितरक/खुदरा विक्रेता को नहीं।

- यदि किसी निर्माता के पास कई कारखाने हैं, जो अलग अलग स्थान पर स्थित है, तो व्यवसाय को प्रत्येक उत्पाद और कारखाने के स्थान के लिए एक अलग आवेदन दाखिल करना होगा।

- ISS के अनुसार उत्पाद का परीक्षण करने के लिए प्रयोगशाला पूरी तरह से परीक्षण उपकरण के साथ-साथ योग्य गुणवत्ता नियंत्रण कर्मियों से सुसज्जित होनी चाहिए।

- ISS मानदंडों और संबंधित SIT के अनुसार सभी उत्पादन मशीनरी और परीक्षण सुविधाएं कारखाने के परिसर में स्थित होनी चाहिए।

- कच्चे माल की प्राप्ति से लेकर अंतिम पैकिंग तक, सभी प्रक्रियाओं को एक ही कारखाने में पूरा किया जाना चाहिए। यदि किसी आउट-सोर्सिंग की आवश्यकता है, तो ब्यूरो से मंजूरी का अनुरोध किया जा सकता है।

- उत्पाद प्रमाणन (Certification) योजना के अंतर्गत आने वाले सभी उत्पादों के लिए तकनीकी दिशानिर्देश 'उत्पाद नियमावली' के रूप में उपलब्ध हैं। उत्पाद नियमावली में नमूना दिशानिर्देश, परीक्षण उपकरण की सूची, निरीक्षण और परीक्षण योजना (एसआईटी), कार्यक्षेत्र का विवरण आदि शामिल हैं। आवेदक ऑडिट और आवेदन जमा करने और BIS प्रमाणन (Certification) के लिए इस उत्पाद नियमावली का उपयोग कर सकता है ताकि अस्वीकृति की संभावना न हो।

BIS ISI प्रमाणपत्र लेने से कंपनियां और उनके उत्पाद को निम्नलिखित लाभ हैं।

- उपभोक्ता का विश्वास प्राप्त करना

- उपभोक्ताओं के स्वास्थ्य का आश्वासन

- उपभोक्ताओं को पता चलता है कि उत्पाद सुरक्षित है और शारीरिक नुकसान से वंचित है।

क्या आप जानते हैं कि भारत में 150 से अधिक उत्पादों के लिए BIS-ISI प्रमाणन (Certification) अनिवार्य है? भले ही BIS प्रमाणपत्र प्राप्त करना स्वैच्छिक है, लेकिन BIS ने नकली वस्तुओ से उपभोक्ताओं की सुरक्षा सुनिश्चित करने के लिए कुछ उत्पादों के लिए BIS प्रमाणपत्र प्राप्त करना अनिवार्य कर दिया है।

BIS ISI प्रमाणन (Certification) के तहत, विभिन्न आवश्यकताएं हैं जिन्हें मोटे तौर पर दो भागों में वर्गीकृत किया गया है: अनिवार्य BIS प्रमाणन (Certification) जिसमें कारखाना निरीक्षण शामिल है और उपभोक्ताओं के विश्वास हासिल करने के लिए स्वैच्छिक BIS प्रमाणन (Certification)।

निम्नलिखित उत्पाद BIS प्रमाणन (Certification) के लिए अनिवार्य हैं:

- भोजन से संबंधित उत्पाद

- कांच और कांच के बने पदार्थ

- सिलेंडर और नियामक

- निर्माण सामग्री

- प्राथमिक बैटरी

- रबर

- ऑयल प्रेशर स्टोव

- तार और केबल्स

- चिकित्सकीय संसाधन

- जूते और चमड़े के उत्पाद

- सीमेंट्स

- मोटर वाहन

- संधारित्र

- अल्युमीनियम

- रासायनिक और उर्वरक

- व्हील रिम और वाल्व

- घरेलू बिजली के सामान

- इस्पात उत्पाद

- इलेक्ट्रिक मोटर और ट्रांसफार्मर

- भोजन से संबंधित उत्पाद

- कांच और कांच के बने पदार्थ

- सिलेंडर और नियामक

- निर्माण सामग्री

- प्राथमिक बैटरी

- रबर

- ऑयल प्रेशर स्टोव

- तार और केबल्स

- चिकित्सकीय संसाधन

- जूते और चमड़े के उत्पाद

- सीमेंट्स

- मोटर वाहन

- संधारित्र

- अल्युमीनियम

- रासायनिक और उर्वरक

- व्हील रिम और वाल्व

- घरेलू बिजली के सामान

- इस्पात उत्पाद

- इलेक्ट्रिक मोटर और ट्रांसफार्मर

भारतीय निर्माताओं के लिए BIS प्रमाणन (Certification) के लिए कई योजनाएं हैं:

सामान्य प्रक्रिया

सामान्य प्रक्रिया के तहत ये निम्नलिखित चरण हैं:

- सबसे पहले, आवेदक को BIS प्रमाणपत्र (Certificate) के लिए जो भी आवश्यकताए हैं उसके लिए तैयारी करनी होती है, विशेष रूप से आवश्यक दस्तावेजों के साथ इन-हाउस लैब स्थापित करना और भारतीय मानकों के अनुसार उत्पाद तैयार करना।

- उसके बाद BIS अधिकारी के द्वारा कारखाने/उद्योग के साथ उत्पादों की निरीक्षण किया जाएगा।

- एक बार निरीक्षण पूरा हो जाने के बाद, उत्पाद के सीलबंद नमूनों को आगे BIS द्वारा अनुमोदित प्रयोगशालाओं में परीक्षण के लिए भेजा जाता है।

- यदि उत्पाद सभी परीक्षण मापदंडों को पूरा करता है, तब BIS से अनुमोदित किया जाता है, और BIS आवेदन जमा करने से 60 से 65 दिनों में भारतीय निर्माताओं के लिए BIS प्रमाणपत्र जारी करता है।

सरलीकृत प्रक्रिया

BIS प्रमाणन (Certification) की यह प्रक्रिया नियमित प्रक्रिया की तुलना में बहुत जल्दी होती है।

- प्रारंभ में, आवेदक भारतीय मानक के अनुसार BIS द्वारा पहले से परीक्षण और अनुमोदित नमूनों की रिपोर्ट प्रस्तुत करता है।

- बाद में, आवेदक को अन्य आवश्यक दस्तावेजों के साथ एक आवेदन और BIS प्रमाणन (Certification) शुल्क जमा करनी होगी।

- आवेदन और दस्तावेजों की जांच के बाद , BIS अधिकारी कारखाने/उद्योग के साथ उत्पादों की निरीक्षण प्रक्रिया का संचालन करेगा।

- एक बार निरीक्षण पूरा हो जाने के बाद, उत्पाद के सीलबंद नमूनों को आगे BIS द्वारा अनुमोदित प्रयोगशालाओं में परीक्षण के लिए भेजा जाता है।

- फिर, यदि भारतीय मानकों के अनुसार उत्पाद सत्यापित और अनुमोदित किया जाता है, तो आवेदन के 35 से 40 दिनों के भीतर BIS द्वारा प्रमाणपत्र प्रदान किया जाता है।

ISI Mark योजना के लिए BIS प्रमाणन (Certification) शुल्क

BIS प्रमाणन (Certification) के नए पंजीकरण के लिए शुल्क नीचे दी गई है। यही शुल्क पुराने मान्यता प्राप्त BIS प्रमाणपत्रों के नवीनीकरण पर भी लागू होती है।

| क्रमांक | शुल्क / शुल्क का प्रकार | राशि | टिप्पणियाँ |

| 1 | आवेदन शुल्क | INR 1000/- | BIS खाते में भुगतान किया जाना है। |

| 2 | लेखापरीक्षा शुल्क | INR 7000/- | BIS खाते में भुगतान किया जाना है। |

| 3 | नमूना परीक्षण शुल्क | जैसा लागू हो | BIS खाते में भुगतान किया जाना है। (नमूना परीक्षण शुल्क उत्पादों और प्रयोगशाला के अनुसार भिन्न हो सकता है) |

| 4 | लाइसेंस शुल्क | INR 1000/- | BIS खाते में भुगतान किया जाना है। |

| 5 | न्यूनतम अग्रिम अंकन शुल्क | वास्तविक शुल्क | BIS खाते में भुगतान किया जाना है। (आईएस मानक के अनुसार अंकन शुल्क अलग है) |

उपरोक्त के अलावा, BIS प्रमाणन (Certification) उत्पाद परीक्षण शुल्क भी लेता है। इसके साथ ही कारखाने के परिसर में भी निवेश की आवश्यकता होती है, विशेष रूप से इन-हाउस फैक्ट्री परीक्षण प्रयोगशालाओं के लिए परीक्षण मशीनरी की स्थापना में जो संपूर्ण BIS प्रमाणन (Certification) प्रक्रिया का महत्वपूर्ण हिस्सा है।

आवश्यक दस्तावेज

BIS प्रमाणन (Certification) आवेदन के लिए आवश्यक दस्तावेज निम्नलिखित हैं:

- उत्पाद मानक के अनुसार प्रयोगशाला परीक्षण रिपोर्ट

- फैक्टरी पंजीकरण दस्तावेज

- उत्पाद निर्माण प्रक्रिया फ्लो चार्ट

- आंतरिक परीक्षण सुविधाएं

- अधिकृत हस्ताक्षरकर्ता और अन्य संबंधित दस्तावेजों का विवरण

निष्कर्ष (Conclusion):

उत्पादों के निर्माताओं या आयातकों के लिए BIS ISI प्रमाणन (Certification) लेना अनिवार्य है यदि उनका उत्पाद BIS Conformity Assessment Scheme के दायरे में आता है। लाइसेंस की शर्तों के उल्लंघन करने पर ,BIS Conformity Assessment Regulations, 2018 के विनियमन 11 के प्रावधान के अनुसार ब्यूरो द्वारा लाइसेंस रद्द किया जा सकता है।

हम, एलेफ इंडिया, 2013 से सभी उत्पाद नियामक अनुपालन के लिए सिंगल-विंडो ऑपरेटर के तौर पर कार्य कर रहे है और उद्योग की मदद कर रहे हैं। दसको के अनुभव के साथ, हम सभी प्रमाणन आवश्यकताओं (Certification Requirement) के अनुपालन में आयातकों या निर्माताओं की सहायता करने में सक्षम हैं ताकि वे आसानी से भारतीय बाजार में उत्पाद का आयात या बिक्री कर सकें और अधिक लाभ कमा सकें।

BIS प्रमाणन (Certification) योजना के तहत उत्पाद

As of now, These are the following products which needs BIS Certificate in India under mandatory certification scheme to Manufacture/Import and sell these products in the INDIAN market. Click on below listed products for more information. Call us at 0-804-803-68-69/91-9990136656 or Email at inbox@alephindia.in for more details.

अक्सर पूछे जाने वाले प्रश्न (FAQ)

उत्पाद पर मानक चिह्न (ISI Mark) का उपयोग करने के लिए निर्माताओं को लाइसेंस देने के लिए BIS द्वारा उत्पाद प्रमाणन (Certification) योजना संचालित किया जाता है।

भारतीय मानको के अनुरूप निर्मित उत्पादों पर मानक चिह्न (ISI MARK) का उपयोग करने के लिए निर्माताओं को BIS लाइसेंस प्रदान किया जाता है।

BIS प्रमाणन (Certification) योजना स्वैच्छिक है; भारत सरकार द्वारा बहुत सारे उत्पादों के लिए BIS Certification अनिवार्य कर दिया गया है। इलेक्ट्रॉनिक्स और आईटी उत्पादों को छोड़कर सभी उत्पाद, उत्पाद प्रमाणन (Certification) योजना (Product Certification Scheme) के अंतर्गत आते हैं।

BIS लाइसेंस प्राप्त करने के लिए, निर्माता के पास भारतीय मानकों (आईएसएस) के अनुसार उत्पाद के लिए आवश्यक विनिर्माण अवसंरचना, उपयुक्त प्रक्रिया नियंत्रण, गुणवत्ता नियंत्रण और परीक्षण क्षमताएं होनी चाहिए। उत्पाद को ISS में उल्लिखित सभी आवश्यकताओं को भी पूरा करना चाहिए।

भारतीय मानक ब्यूरो उत्पाद पर मानक चिह्न (ISI MARK) का उपयोग करने के लिए BIS (Conformity Assessment) Regulations, 2018 की अनुसूची- II की योजना- I के अनुसार निर्माता को लाइसेंस प्रदान करता है।

BIS प्रमाणन (Certification) की पूरी प्रक्रिया ऊपर उल्लिखित है। भारत में BIS प्रमाणन (Certification) प्राप्त करने के लिए, आपको ऊपर वर्णित प्रक्रिया का पालन करना होगा; अधिक सहायता के लिए कृपया एलेफ इंडिया से संपर्क करें।

BIS प्रमाणन (Certification) के लिए आवश्यक दस्तावेज का उल्लेख ऊपर किया गया है। अधिक जानकारी के लिए आप एलेफ इंडिया (Aleph India) से संपर्क कर सकते हैं।

BIS प्रमाणन (Certification) योजना स्वैच्छिक है; भारत सरकार द्वारा बहुत सारे उत्पादों के लिए BIS Certification अनिवार्य कर दिया गया है। वह उत्पाद जो अनिवार्य BIS प्रमाणन (Certification) के अंतर्गत आते हैं, BIS के वेबसाइट पर उपलब्ध हैं। यदि आपका उत्पाद उस सूची में है, तो आपके लिए BIS लाइसेंस (BIS LICENCE) प्राप्त करना अनिवार्य है।

BIS REGISTRATION FOR ELECTRONIC & IT PRODUCT

In the era of globalization, world trade is growing rapidly and henceforth, Manufacturing and Import/Export businesses are also growing drastically...View More

BIS CERTIFICATE FOR FOREIGN MANUFACTURER

The Economy of India-the fastest developing economy on the globe with the capabilities that help it matches up with the biggest international...View More

PRODUCT CERTIFICATION SCHEME (ISI MARK) FOR DOMESTIC MANUFACTURERS

Anything a person buys from food to cars, clothes to electronics, branded to unnamed products there is always a question that wanders in one’s...View More

WIRELESS PLANNING AND COORDINATION (WPC)

WPC: Wireless means communication done from one point to another point without the wires and cables. Electromagnetic waves carry the ...View More

BUREAU OF ENERGY EFFICIENCY (BEE) CERTIFICATE

BEE CERTIFICATE: Energy is the future, and its conservation is the way of the bright future. Everyone claims the environment is important...View More

E-WASTE MANAGEMENT

E-waste is one of the world's fastest-growing trash streams. We currently manufacture almost 50 million tones of it each year...View More

Request a call back.

Would you like to speak to one of our Senior Technical advisers over the phone? Just submit your details and we’ll be in touch shortly. You can also email us if you would prefer.

BIS REGISTRATION FOR ELECTRONIC & IT PRODUCT

In the era of globalization, world trade is growing rapidly and henceforth, Manufacturing and Import/Export businesses are also growing drastically...View More

BIS CERTIFICATE FOR FOREIGN MANUFACTURER

The Economy of India-the fastest developing economy on the globe with the capabilities that help it matches up with the biggest international...View More

PRODUCT CERTIFICATION SCHEME (ISI MARK) FOR DOMESTIC MANUFACTURERS

Anything a person buys from food to cars, clothes to electronics, branded to unnamed products there is always a question that wanders in one’s...View More

WIRELESS PLANNING AND COORDINATION (WPC)

WPC: Wireless means communication done from one point to another point without the wires and cables. Electromagnetic waves carry the ...View More

BUREAU OF ENERGY EFFICIENCY (BEE) CERTIFICATE

BEE CERTIFICATE: Energy is the future, and its conservation is the way of the bright future. Everyone claims the environment is important...View More

E-WASTE MANAGEMENT

E-waste is one of the world's fastest-growing trash streams. We currently manufacture almost 50 million tones of it each year...View More

View All Services

Request a call back.

Would you like to speak to one of our Senior Technical advisers over the phone? Just submit your details and we’ll be in touch shortly. You can also email us if you would prefer.